Mechanical Parameter

|

Model |

DB-8200 |

|

Size (Bag Width) |

70–200 mm |

|

Filling Range |

10–1000 g |

|

Packing Speed |

40–60 bags/min (varies by filling) |

|

Average Precision |

≤ ±1% |

|

Total Power |

2.5 KW |

|

Dimensions (L×W×H) |

1900 × 1570 × 1700 mm |

|

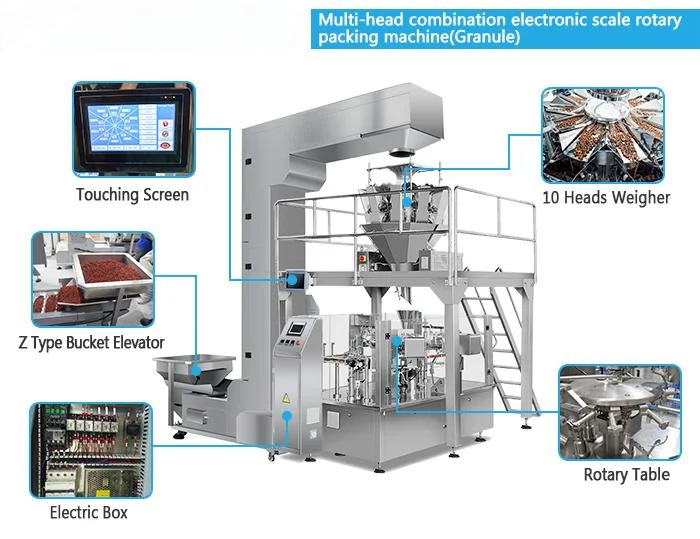

Workflow |

Bag giving → Coding → Opening → Filling 1 → Filling 2 → Auxiliary → Exhaust → Sealing |

|

Applicable Materials

|

Block Materials

|

|

Granular Materials

|

|

|

Powder Materials

|

|

|

Liquid/Paste Materials

|

|

|

Pickled Products

|

|

|

Other Bagging Materials

|

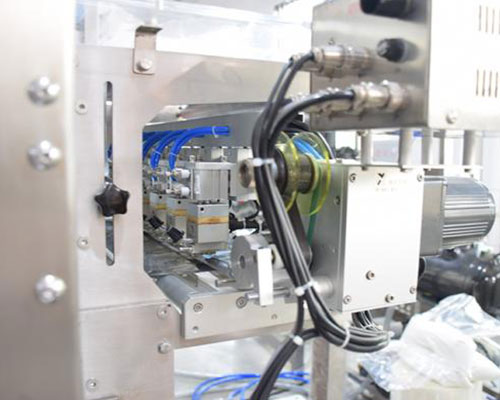

The cookie packaging machine from DBAO Packaging Machinery is designed to deliver fast, reliable, and hygienic packaging for a wide variety of baked goods. This automatic cookie packaging machine ensures precise portioning, consistent sealing, and attractive presentation for cookies, biscuits, crackers, and other bakery products. Built with food-grade stainless steel and equipped with advanced servo-controlled systems, it meets strict hygiene standards while maximizing operational efficiency. The machine supports multiple packaging formats, including pillow packs, flow packs, and multi-lane packs, making it suitable for both small artisan bakeries and large industrial production lines. With intuitive touchscreen controls, quick changeovers, and low maintenance requirements, this machine helps manufacturers streamline production, reduce labor costs, and consistently deliver high-quality, visually appealing packaged cookies.

Applications

- Cookies & Biscuits – Individual or multi-pack packaging for retail or wholesale.

- Crackers & Snack Bars – Consistent, hygienic, and visually appealing packaging.

- Bakery Items – Cakes, pastries, and baked goods requiring protective wrapping.

- Promotional or Sample Packs – Small packages for marketing or trial purposes.

- Industrial Production Lines – High-speed automated packaging for mass production.

Why Choose DBAO Packaging Machinery

- Proven Expertise – Over 14 years of experience in bakery and food packaging machinery.

- Customizable Solutions – Machines tailored to your cookie type, packaging format, and production volume.

- Global Support & Installation – Technical guidance, on-site training, and after-sales service worldwide.

- Strict Quality Assurance – Each machine tested for precision, reliability, and hygiene compliance.

- Eco-Friendly Options – Compatible with recyclable and sustainable packaging materials.

- Comprehensive After-Sales Service – Spare parts availability and 24/7 support for uninterrupted operation.