Mechanical Parameter

Model | DBY-4 | DBY-6 | DBY-8 |

Capacity | Max. 30 cycles/min | ||

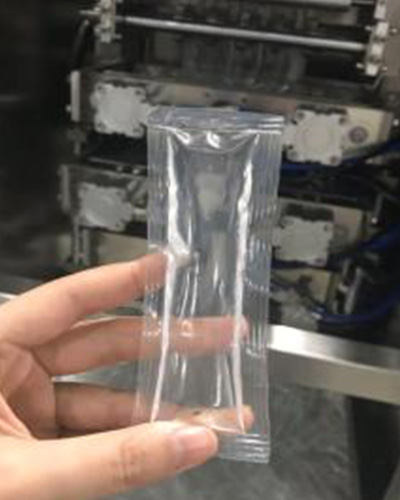

Bag Size | L: 50–180 mm, W: 20–100 mm | ||

Film Width & Thickness | 0.05–0.1 mm | ||

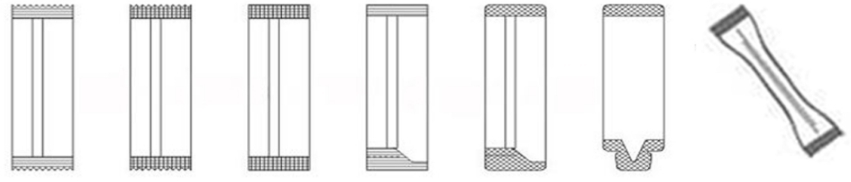

Cutting Types | 1. Straight Cutting | ||

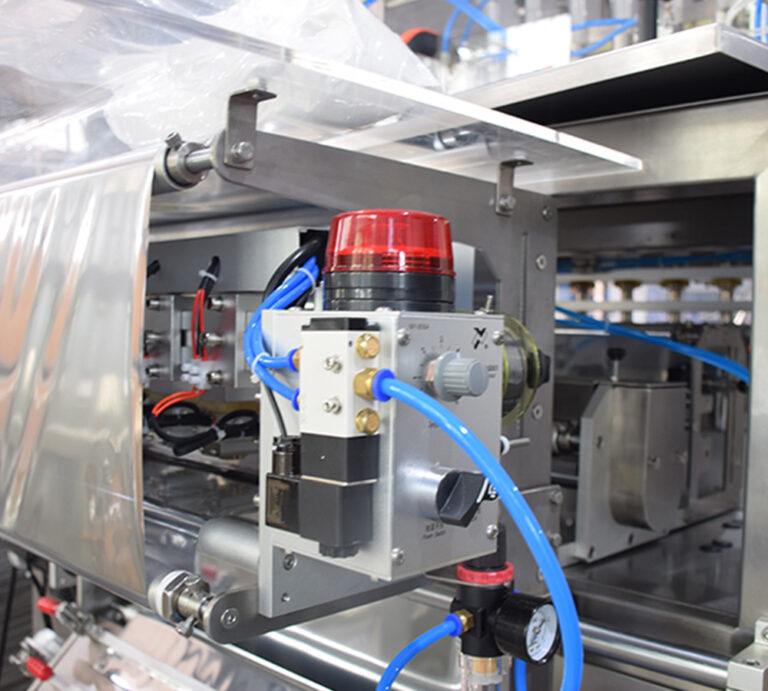

Air&Power | 0.8 Mpa, 0.8 m³/min, 3.5 kW | 0.8 Mpa, 1 m³/min, 4.5 kW | 0.8 Mpa, 1.5 m³/min, 5 kW |

Weight | 350 kg | 450 kg | 550 kg |

The sauce pouch packing machine from DBAO Packaging Machinery is specifically engineered to provide precise, efficient, and hygienic packaging for a wide variety of sauces, condiments, and liquid seasonings. Designed to handle products of varying viscosities, this machine ensures accurate filling, leak-proof sealing, and consistent pouch formation, preserving product freshness and flavor. Our sauce pouch packing machine supports multiple pouch formats, including spout pouches, stick pouches, and quad-sealed bags, making it versatile for both small-scale and large-scale production lines. Constructed with high-quality components such as Panasonic PLCs, advanced servo motors, and stainless steel parts, the machine delivers reliable, long-lasting performance. With an intuitive touchscreen interface, quick product changeovers, and minimal maintenance requirements, manufacturers can achieve higher productivity, reduced labor costs, and professional market-ready packaging.

Key Features

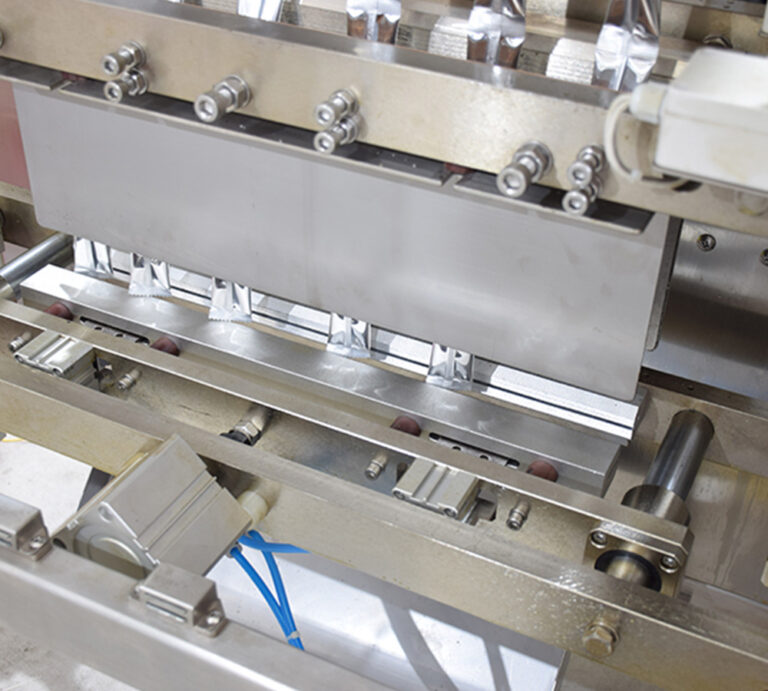

- High-Precision Filling & Sealing – Advanced servo-controlled filling ensures accurate portioning for sauces of all viscosities, preventing leakage and product waste.

- Multi-Format Compatibility – Supports spout pouches, stick packs, quad-sealed bags, and customized pouch designs, providing flexibility for different product lines.

- Premium Durable Components – All food-contact parts made of stainless steel; equipped with Panasonic PLCs and high-performance servo motors for long-lasting and reliable operation.

- User-Friendly Operation – Intuitive touchscreen interface for easy setup, real-time monitoring, and quick adjustments, reducing operator error and training time.

- Hygienic & Easy Maintenance – Full stainless steel construction meets food-grade standards, designed for effortless cleaning and routine maintenance.

- Customizable Production Lines – Adjustable parameters for various sauce types, pouch sizes, production speeds, and optional integration with weighing, labeling, or nitrogen flushing systems.

- Energy-Efficient & Stable Performance – Optimized control systems reduce power consumption while maintaining consistent high-speed operation.

Applications

- Packaging condiments such as ketchup, mustard, mayonnaise, and salad dressings.

- Filling and sealing sauces including soy sauce, chili sauces, teriyaki, marinades, and cooking sauces.

- Packaging liquid seasonings, flavored oils, nutritional syrups, and herbal liquids.

- Suitable for both small-batch artisanal production and large-scale industrial production lines.

- Ideal for retail-ready pouches, ready-to-eat sauce kits, food delivery packets, and export-oriented packaging.

- Can be integrated into fully automated production lines including weighing, filling, sealing, labeling, and inspection systems.