Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | 35–70 Bags/Min | 35–70 Bags/Min |

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Machine Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

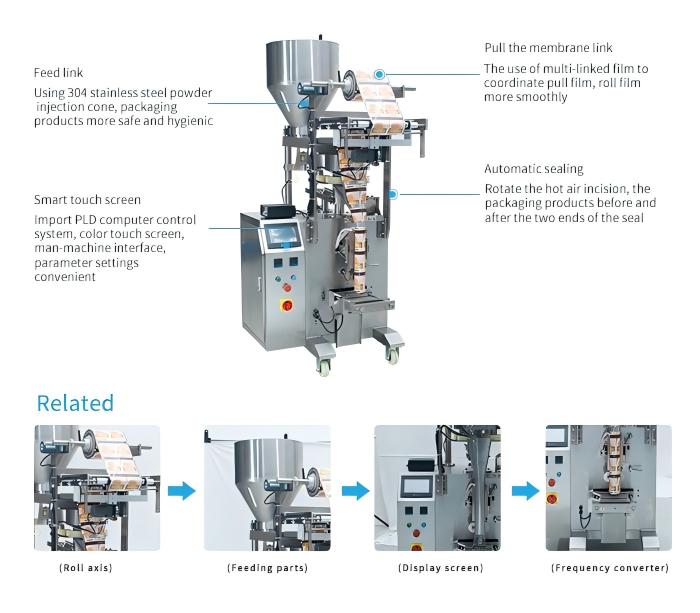

DBAO’s bread packaging machine is designed to provide bakery manufacturers with a reliable, high-speed solution for packaging sliced or whole loaves while maintaining freshness and product integrity. With increasing demand for ready-to-sell bread, the bread packaging machine ensures consistent sealing, hygienic handling, and minimal product damage.

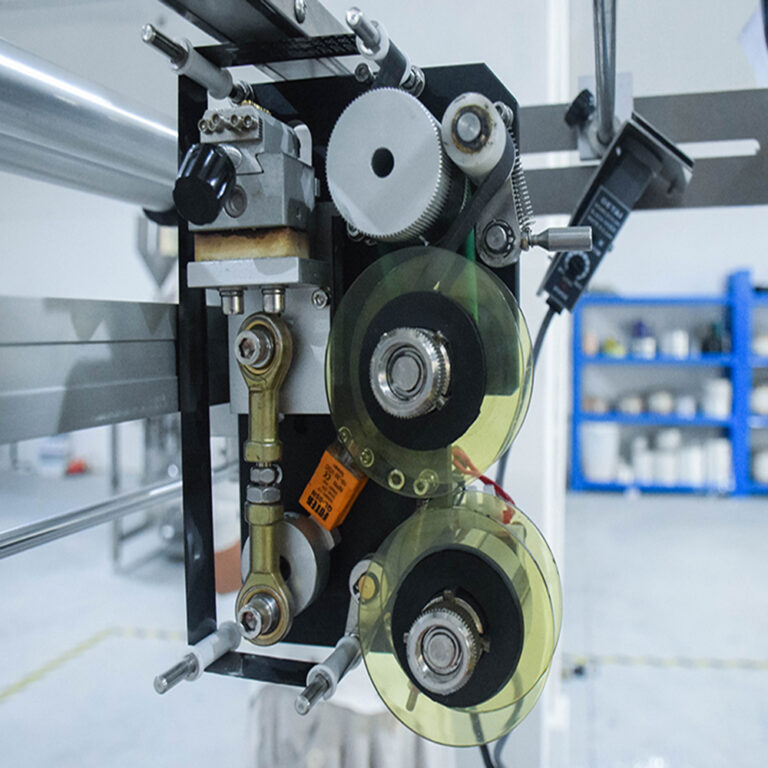

Equipped with advanced PLC controls, smart sensors, and durable stainless-steel construction, this machine streamlines the entire packaging process, from feeding and wrapping to sealing and labeling. Its compact footprint and user-friendly interface allow operators to quickly adjust settings for different bread sizes and packaging formats. By combining efficiency, precision, and ease of operation, DBAO’s bread packaging machine helps bakeries reduce labor costs, improve production speed, and deliver high-quality, consumer-ready bread consistently.

Applications

- Bakery Industry: Sliced bread, whole loaves, specialty artisan bread.

- Retail Packaging: Supermarkets, convenience stores, and direct-to-consumer packs.

- Food Service & Catering: Pre-packaged bread for restaurants, cafes, and catering services.

- Export Packaging: Ensures bread remains fresh during shipping and distribution.

Why Choose DBAO Packaging Machinery?

- Professional Expertise: Over 14 years of experience in bakery and food packaging solutions.

- Global Recognition: Trusted by clients in more than 70 countries worldwide.

- Customized Solutions: OEM and ODM services tailored to bread size, packaging type, and production volume.

- Durable Components: Premium electrical and mechanical parts ensure long-term reliability.

- Complete Packaging Line Support: Integration with labeling, check-weighing, and collection systems.

- Dedicated Customer Service: Installation, training, and 24/7 technical support.

- Proven Efficiency: Machines designed to maintain consistent quality at high production speeds.