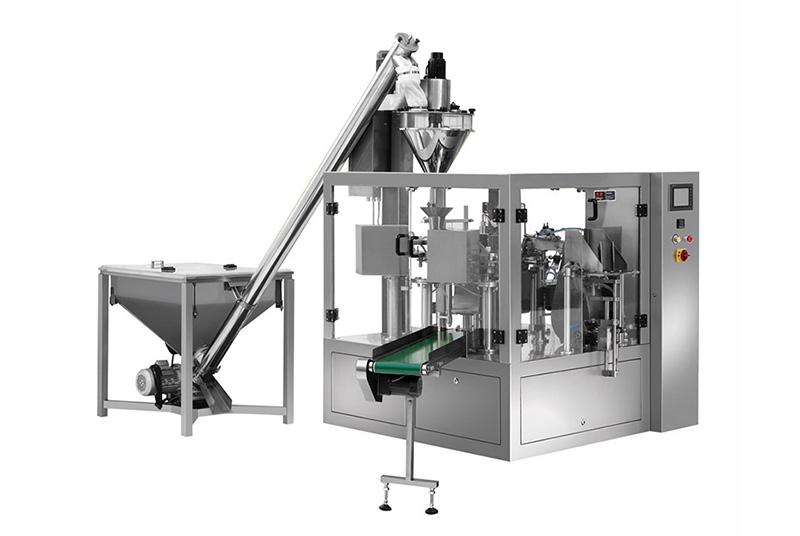

Mechanical Parameter

|

Model |

DB-8200 |

|

Size (Bag Width) |

70–200 mm |

|

Filling Range |

10–1000 g |

|

Packing Speed |

40–60 bags/min (varies by filling) |

|

Average Precision |

≤ ±1% |

|

Total Power |

2.5 KW |

|

Dimensions (L×W×H) |

1900 × 1570 × 1700 mm |

|

Workflow |

Bag giving → Coding → Opening → Filling 1 → Filling 2 → Auxiliary → Exhaust → Sealing |

|

Applicable Materials

|

1. Block Materials

|

|

2. Granular Materials

|

|

|

3. Powder Materials

|

|

|

4. Liquid/Paste Materials

|

|

|

5. Pickled Products

|

|

|

6. Other Bagging Materials

|

Modern packaging machinery technology represents the forefront of automated production, combining efficiency, precision, and versatility in a single system. This technology enables manufacturers to handle a wide range of products, from powders, liquids, and granules to solid goods, while ensuring consistent quality, hygienic operation, and minimal material waste. By integrating intelligent control systems, advanced sensors, and robust construction, packaging machinery technology supports multiple packaging formats such as pouches, stick packs, pillow bags, and gusseted bags. These solutions not only optimize production speed and reduce downtime but also improve operational safety and compliance with industry standards. Manufacturers adopting this technology can achieve scalable, reliable, and high-performance packaging processes that meet modern market demands.

Key Features

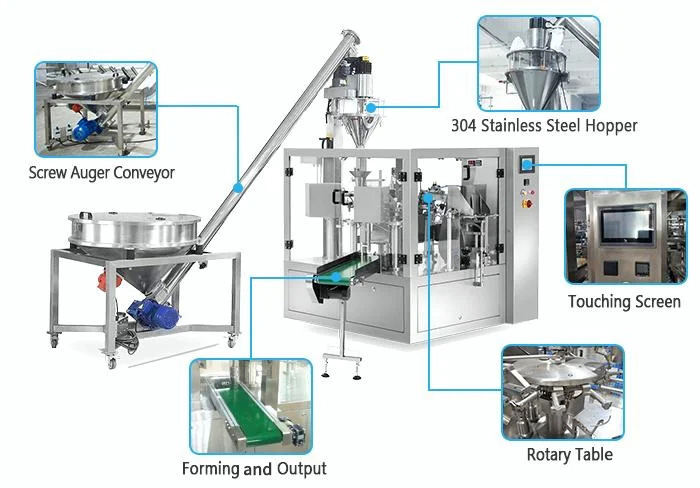

- Automation & Precision: High-accuracy filling and sealing for consistent results.

- Versatile Formats: Compatible with a variety of bag types and sizes.

- Hygienic Construction: Food-grade materials and stainless-steel components ensure safety.

- User-Friendly Interface: Touchscreen controls for easy operation and monitoring.

- Durable & Efficient: Designed to minimize maintenance and maximize uptime.

Why Choose DBAO Packaging Machinery?

- Proven Expertise: Over 14 years in designing and manufacturing advanced packaging solutions.

- Global Presence: More than 1,500 machines installed across 70+ countries.

- Tailored Solutions: Custom systems to meet specific product and production requirements.

- Innovative Engineering: Continuous R&D ensures cutting-edge automation and precision.

- Comprehensive Support: End-to-end service from consultation and installation to training and after-sales assistance.