Mechanical Parameter

|

Model |

DB-8200 |

|

Size (Bag Width) |

70–200 mm |

|

Filling Range |

10–1000 g |

|

Packing Speed |

40–60 bags/min (varies by filling) |

|

Average Precision |

≤ ±1% |

|

Total Power |

2.5 KW |

|

Dimensions (L×W×H) |

1900 × 1570 × 1700 mm |

|

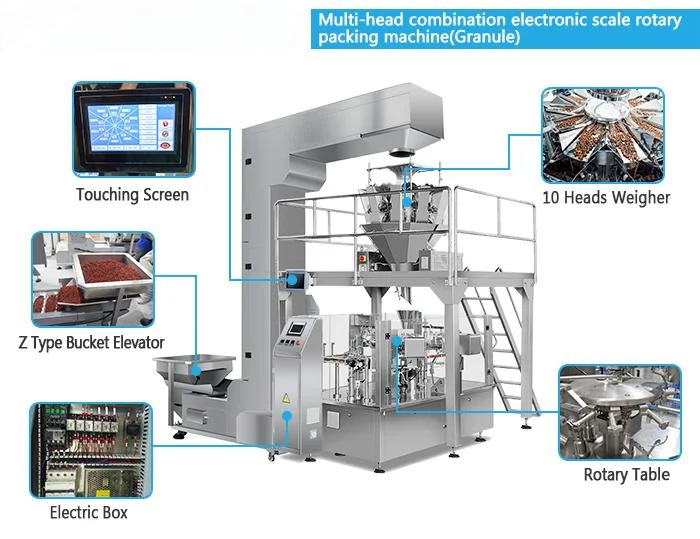

Workflow |

Bag giving → Coding → Opening → Filling 1 → Filling 2 → Auxiliary → Exhaust → Sealing |

|

Applicable Materials

|

Block Materials

|

|

Granular Materials

|

|

|

Powder Materials

|

|

|

Liquid/Paste Materials

|

|

|

Pickled Products

|

|

|

Other Bagging Materials

|

The production of packaging is a critical process for businesses aiming to enhance efficiency, ensure product safety, and maintain consistent quality. Advanced systems in this field integrate automated filling, sealing, and handling technologies, enabling precise and uniform packaging for powders, liquids, granules, and solid items. With versatile capabilities, these solutions support various formats such as pouches, stick packs, gusseted bags, and pillow bags, allowing manufacturers to adapt to different product types and market requirements. Designed with durable construction, intelligent controls, and user-friendly interfaces, equipment for the production of packaging streamlines operations, reduces waste, and maximizes productivity while ensuring compliance with hygiene and safety standards across industries.

Applications

Production of packaging solutions is widely applied in:

- Food & Beverage: Snacks, coffee, tea, sauces, frozen foods, and powders.

- Pharmaceuticals & Healthcare: Powders, granules, capsules, and liquid medications.

- Chemicals & Industrial Products: Detergents, fertilizers, and specialty powders.

- Cosmetics & Personal Care: Lotions, gels, creams, and single-use items.

Why Choose DBAO Packaging Machinery?

- Extensive Experience: Over 14 years in designing and manufacturing advanced packaging equipment.

- Global Installations: More than 1,500 machines operating successfully in 70+ countries.

- Customizable Solutions: Tailored systems to meet specific product and production requirements.

- Innovative Technology: Continuous R&D ensures efficient, reliable, and precise operations.

- Comprehensive Support: Full-service assistance including consultation, installation, training, and after-sales maintenance.