Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | ||

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Machine Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

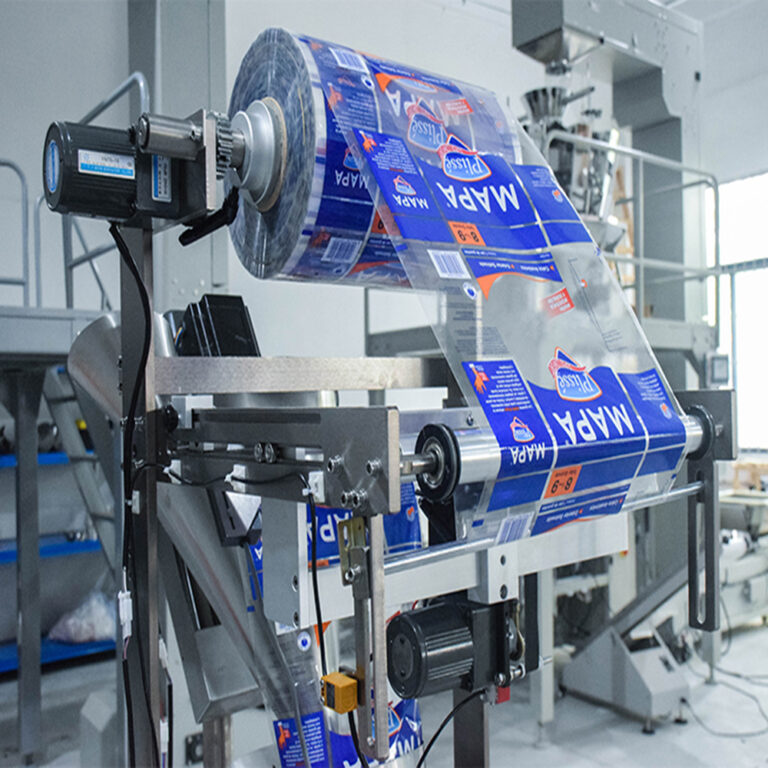

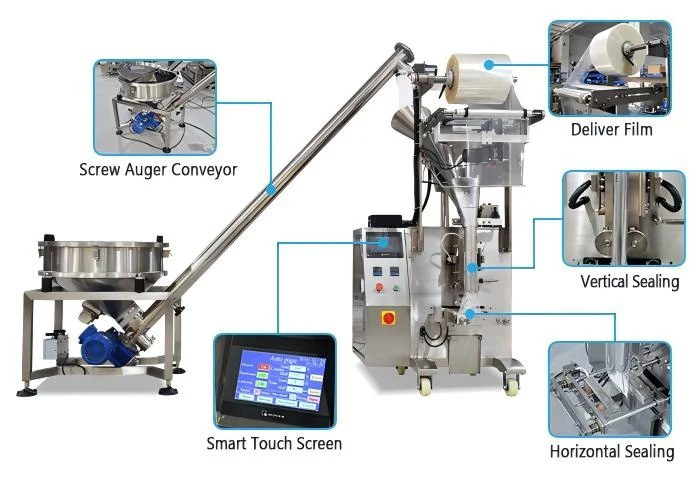

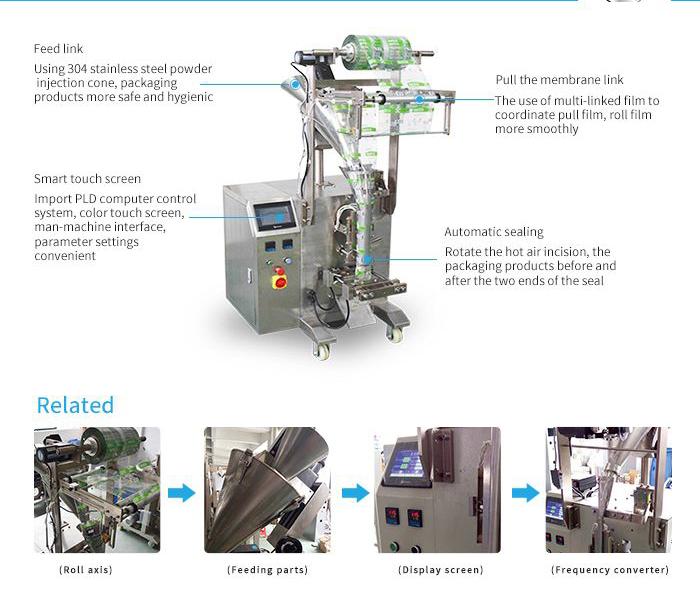

Automated food packaging systems are revolutionizing the way manufacturers handle, package, and distribute food products. Designed to optimize efficiency, accuracy, and hygiene, these systems seamlessly integrate filling, sealing, and labeling processes into a single, high-speed operation. Capable of handling a wide variety of products such as powders, liquids, granules, snacks, and frozen foods, automated food packaging systems ensure uniform portioning, secure sealing, and reduced material waste.

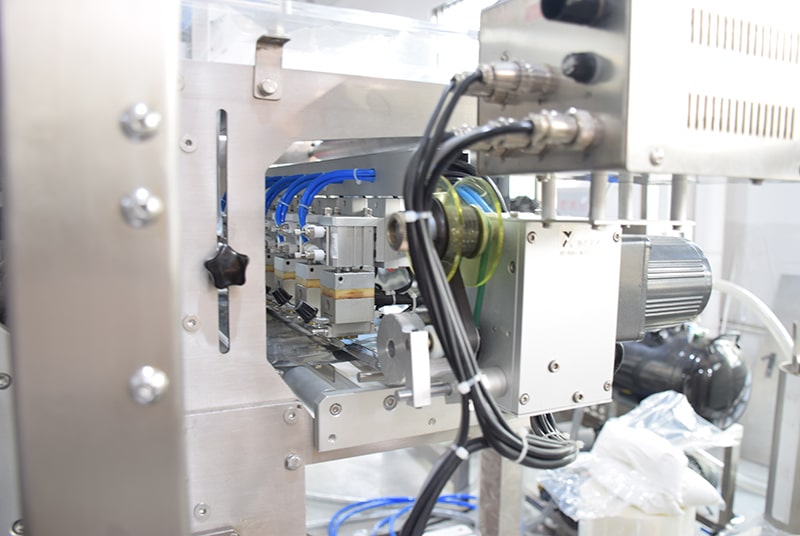

With flexible packaging options including stand-up pouches, pillow bags, stick packs, and gusseted bags, these systems enable manufacturers to adapt quickly to market trends and customer demands. Featuring intelligent control panels, durable stainless-steel construction, and easy maintenance, these solutions offer high reliability and productivity for modern food production lines.

Key Features

- High-Speed & Efficient Operation: Maximizes production output while maintaining precise packaging standards.

- Versatile Packaging Formats: Supports a variety of bag types and sizes for different food products.

- Precision Filling & Sealing: Ensures consistent product weight, secure seals, and minimal waste.

- Hygienic & Durable Design: Stainless steel and food-grade materials for safe, long-lasting operation.

- User-Friendly Controls: Touchscreen interface allows simple setup, monitoring, and adjustments.

Applications

Automated food packaging systems are widely used in:

- Snack Foods: Chips, nuts, puffed cereals, and confectionery.

- Frozen Foods: Vegetables, fruits, meat, and ready-to-eat meals.

- Liquids & Powders: Sauces, beverages, coffee, tea, protein powders, and spices.

- Specialty & Health Products: Nutritional supplements, vitamins, and pet food.