Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | ||

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

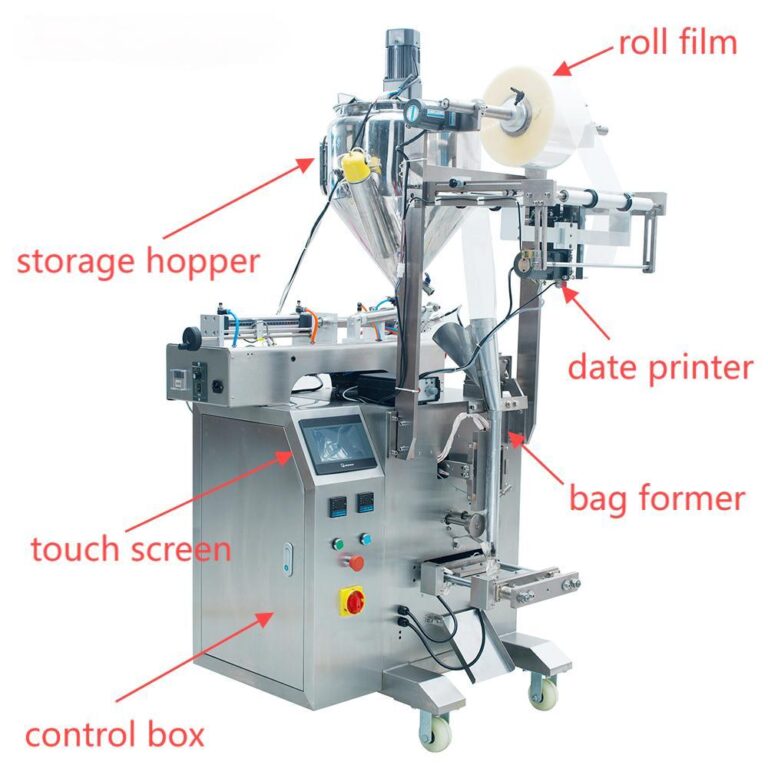

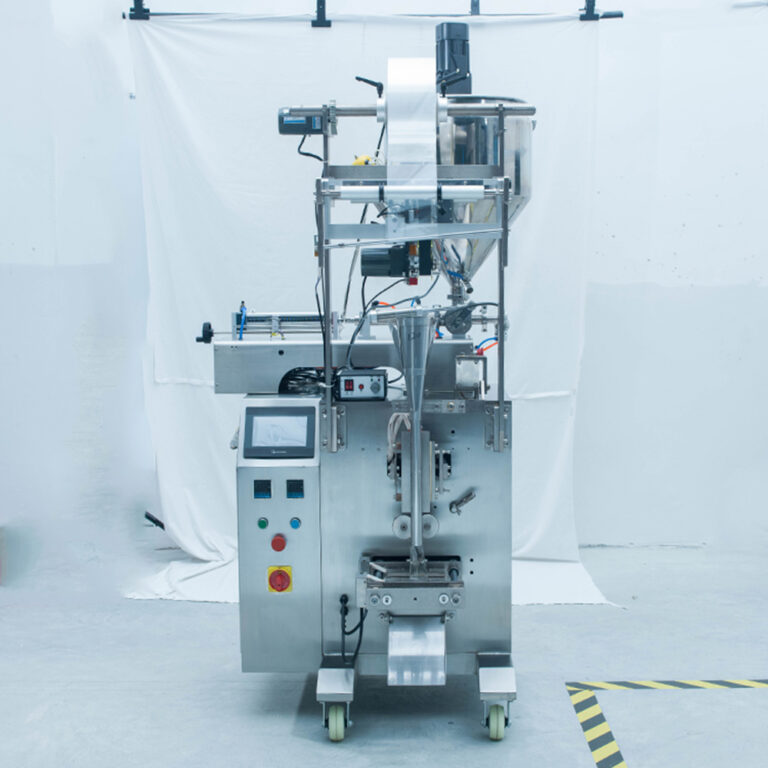

The vertical form fill machine is an advanced packaging solution engineered to optimize production efficiency, accuracy, and reliability. Designed for a wide range of products including powders, liquids, granules, and solid items, this machine provides precise filling and secure sealing in various packaging formats such as pillow bags, gusseted pouches, stand-up pouches, and stick packs. Equipped with intelligent automation, durable stainless-steel construction, and user-friendly control interfaces, the vertical form fill machine ensures high-speed operation, minimal downtime, and reduced material waste.

Its versatile design allows manufacturers to adapt quickly to changing product requirements and market demands, making it an essential solution for food, pharmaceutical, chemical, and personal care industries seeking consistent, hygienic, and scalable packaging processes.

Key Features

- High-Speed Operation: Ensures maximum production output without sacrificing accuracy.

- Multiple Packaging Formats: Compatible with a variety of pouches and bag types.

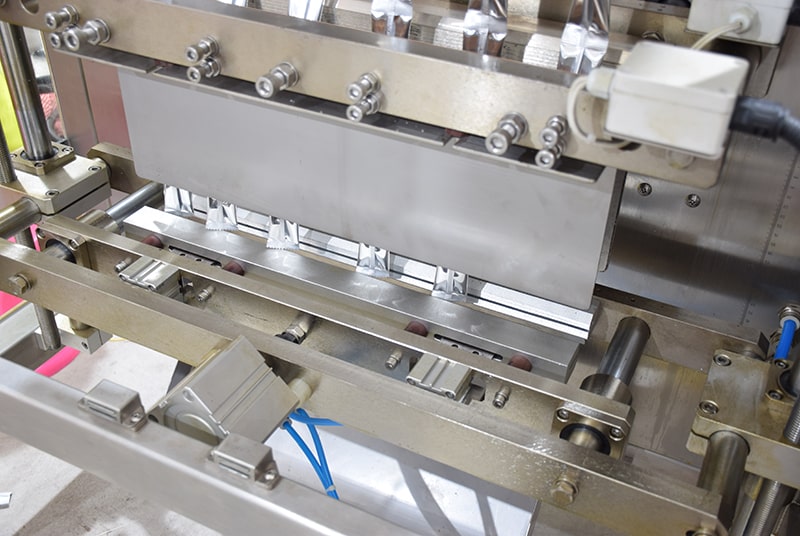

- Precision Filling & Sealing: Guarantees leak-proof and uniform packaging.

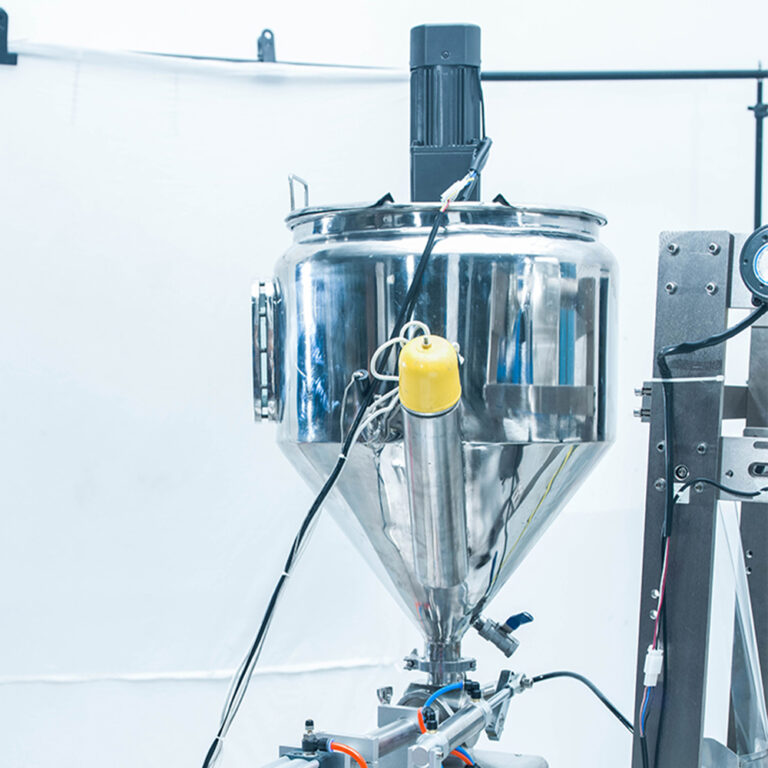

- Hygienic & Durable Construction: Stainless steel and food-grade materials for safe and long-lasting operation.

- User-Friendly Controls: Touchscreen interface for simple setup, monitoring, and adjustment.

Why Choose DBAO Packaging Machinery?

- Proven Expertise: Over 14 years of experience in designing and producing advanced packaging equipment.

- Global Installations: More than 1,500 machines operating in over 70 countries worldwide.

- Customizable Solutions: Tailored systems to meet specific product and production needs.

- Innovative Engineering: Advanced automation ensures reliable, precise, and efficient performance.

- Comprehensive Support: End-to-end service from consultation and installation to training and after-sales maintenance.