Mechanical Parameter

| Similar Mainframe Model Specifications (Product Size Selection Models) | |||||

| Type | DB-420 | DB-520 | DB-720 | DB-900 | DB-1200 |

Film Width | Max. 420 mm | Max. 520 mm | Max. 720 mm | Max. 900 mm | Max. 1200 mm |

Bag Length | 80-300 mm | 80-350 mm | 180-350 mm | 100-600 mm | 100-1000 mm |

Bag Width | 60-200 mm | 100-250 mm | 100-500 mm | 260-430 mm | 290-580 mm |

Film Roll Diameter | Max. 320 mm | Max. 320 mm | Max. 320 mm | Max. 400 mm | Max. 400 mm |

Packaging Rate | 5–60 Bags/Min | 5–60 Bags/Min | 5–55 Bags/Min | 5–20 Bags/Min | 5–20 Bags/Min |

Power | 220V 50/60 Hz, 2 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 4.5 kW | 220V 50/60 Hz, 5 kW |

Measurement Range | 150–1500 ml | 2000 ml | 4000 ml | 1-25 ml | 1.5-45 ml |

Film Thickness | 0.04-0.08 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm |

Machine Size (LxWxH) | 1217x1015x1343 mm | 1488x1080x1490 mm | 1780x1350x2050 mm | 2305x1686x2725 mm | 2900x2050x3500 mm |

Weight | About 650 KG | About 680 KG | About 750 KG | ||

Certification | CE/SGS/ISO Certification | ||||

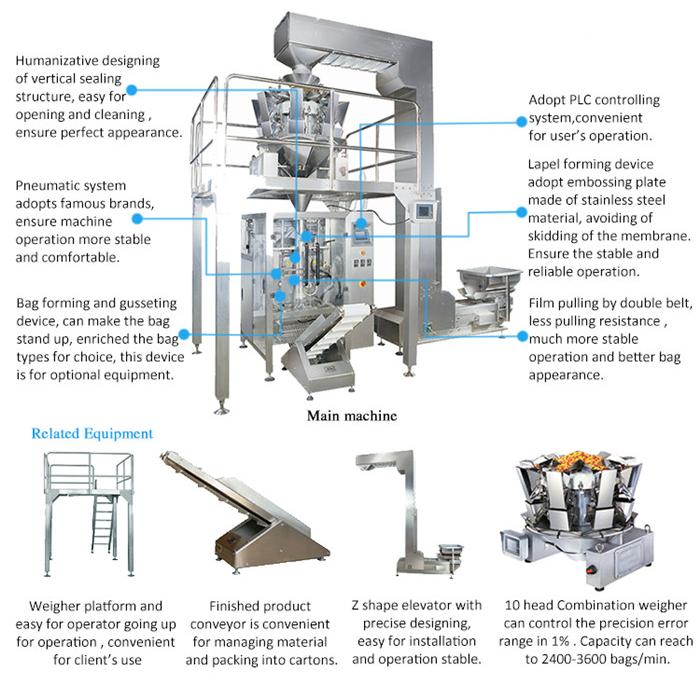

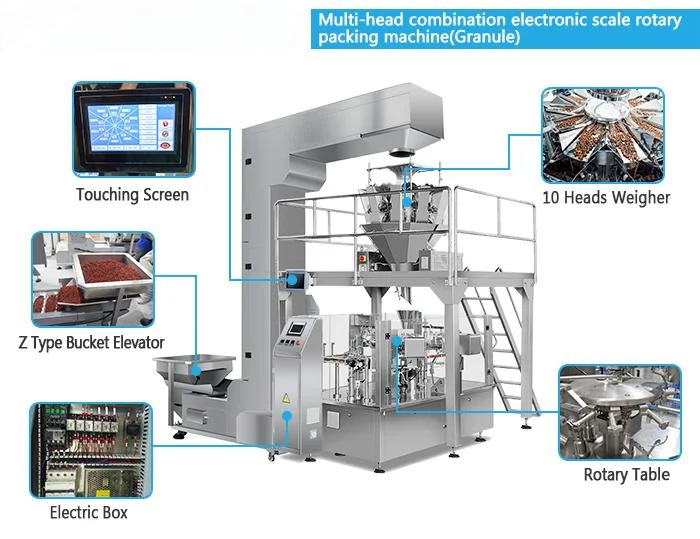

The rotary pouch filling machine is an advanced packaging solution designed to deliver high-speed, accurate, and reliable filling for a wide range of products. Ideal for powders, liquids, granules, and solid items, this machine integrates filling, sealing, and pouch handling in a compact, automated system. Its rotary mechanism ensures continuous production with minimal downtime while maintaining precise portion control and secure sealing for every pouch. With the capability to handle multiple pouch types including stand-up pouches, gusseted bags, pillow bags, and stick packs, the rotary pouch filling machine offers versatility for manufacturers aiming to meet diverse market and packaging demands. Built with durable stainless-steel construction, intuitive control systems, and user-friendly interfaces, it ensures hygienic operation, easy maintenance, and high productivity.

Applications

Rotary pouch filling machines are widely used in:

- Food & Beverage: Snacks, coffee, tea, sauces, frozen foods, and powders.

- Pharmaceuticals & Healthcare: Powdered supplements, granules, liquid medications, and capsules.

- Chemicals & Industrial Products: Fertilizers, detergents, and specialty powders.

- Cosmetics & Personal Care: Lotions, gels, creams, and single-use products.

Why Choose DBAO Packaging Machinery?

- Proven Expertise: Over 14 years of experience designing and manufacturing reliable packaging solutions.

- Global Reach: More than 1,500 machines installed in over 70 countries worldwide.

- Customizable Systems: Tailored solutions to meet specific product types and production requirements.

- Advanced Engineering: Cutting-edge automation ensures precise, consistent, and efficient operation.

- Comprehensive Support: End-to-end service including consultation, installation, training, and after-sales assistance.