Mechanical Parameter

|

Model |

DB-8200 |

|

Size (Bag Width) |

70–200 mm |

|

Filling Range |

10–1000 g |

|

Packing Speed |

40–60 bags/min (varies by filling) |

|

Average Precision |

≤ ±1% |

|

Total Power |

2.5 KW |

|

Dimensions (L×W×H) |

1900 × 1570 × 1700 mm |

|

Workflow |

Bag giving → Coding → Opening → Filling 1 → Filling 2 → Auxiliary → Exhaust → Sealing |

|

Applicable Materials

|

Block Materials

|

|

Granular Materials

|

|

|

Powder Materials

|

|

|

Liquid/Paste Materials

|

|

|

Pickled Products

|

|

|

Other Bagging Materials

|

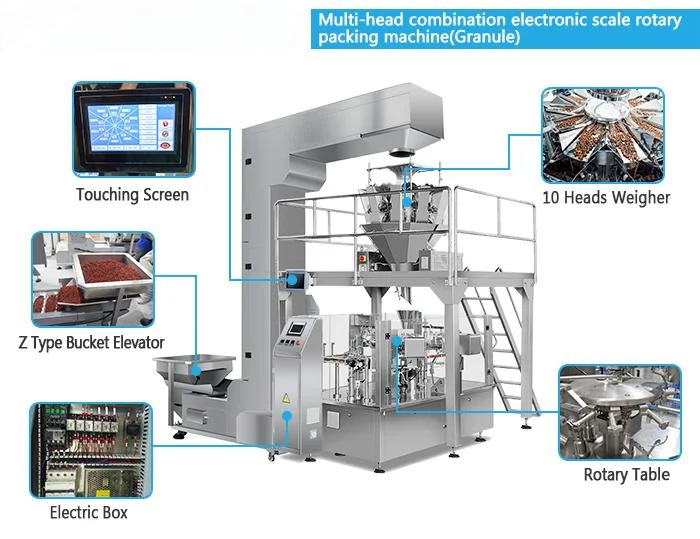

As production demands grow, manufacturers require packaging equipment that is fast, reliable, and flexible. A vertical bagging machine from DBAO Packaging Machinery is the ideal solution for businesses seeking maximum efficiency without compromising product quality. Engineered with advanced automation, these machines perform bag forming, filling, and sealing in a continuous process, drastically reducing manual labor and increasing throughput.

DBAO’s vertical bagging machines are designed for versatility, handling a wide range of packaging formats including pillow bags, gusset bags, quad-seal bags, zipper pouches, and stick packs. This adaptability ensures that manufacturers can respond to evolving market needs while maintaining consistent, high-quality packaging. Built with premium-grade components such as Panasonic PLCs and servo systems, our machines deliver long-lasting stability, accurate dosing, and minimal downtime.

Key Features

- Wide Bagging Capability: Supports pillow, gusset, quad seal, zipper, and stick bag formats.

- Precision Filling: Accurate measurement for powders, liquids, granules, and solids.

- High-Speed Output: Designed for large-scale operations with consistent results.

- Smart Control Systems: Panasonic PLC and servo technology for smooth, intelligent performance.

- Robust Build: Durable construction with quality components for long service life.

- Compact & User-Friendly: Space-efficient design with easy setup, operation, and maintenance.

Why Choose DBAO Packaging Machinery?

- Industry Expertise: Over 14 years of experience in automated packaging solutions.

- Global Recognition: More than 1,500 machines installed in 70+ countries.

- Innovative Design: Third-generation engineering for efficiency, speed, and reliability.

- Complete Solutions: From vertical bagging machines to auxiliary systems like check weighers and labeling machines.

- Dedicated Service: 24/7 technical support, quick spare part supply, and professional after-sales assistance.