Mechanical Parameter

|

Model |

DBY-4 |

DBY-6 |

DBY-8 |

|

Capacity |

Max. 30 cycles/min |

||

|

Bag Size |

L: 50–180 mm, W: 20–100 mm |

||

|

Film Width & Thickness |

0.05–0.1 mm |

||

|

Cutting Types |

1. Straight Cutting |

||

|

Air & Power |

0.8 Mpa, 0.8 m³/min, 3.5 kW |

0.8 Mpa, 1 m³/min, 4.5 kW |

0.8 Mpa, 1.5 m³/min, 5 kW |

|

Weight |

350 kg |

450 kg |

550 kg |

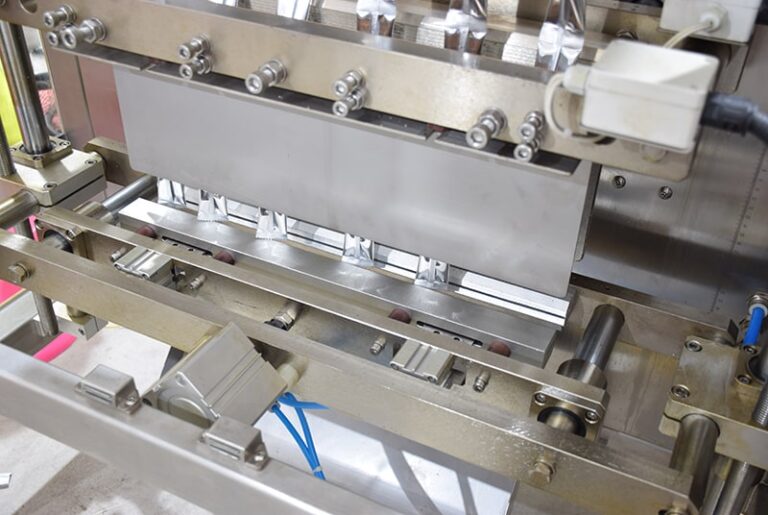

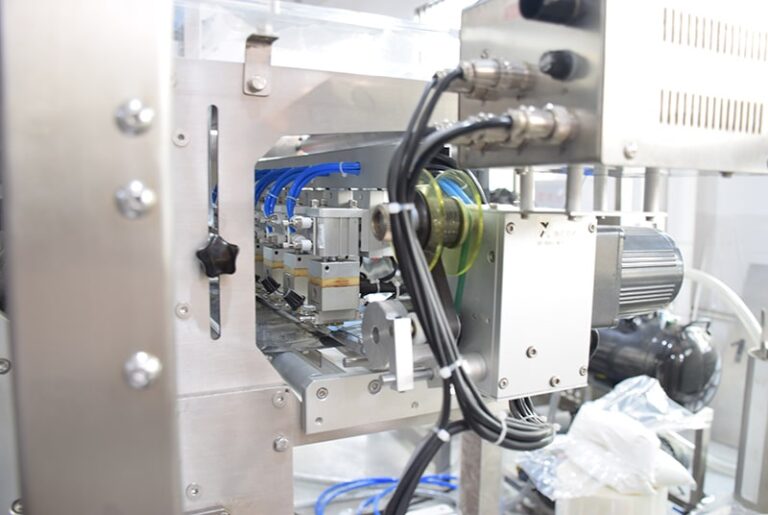

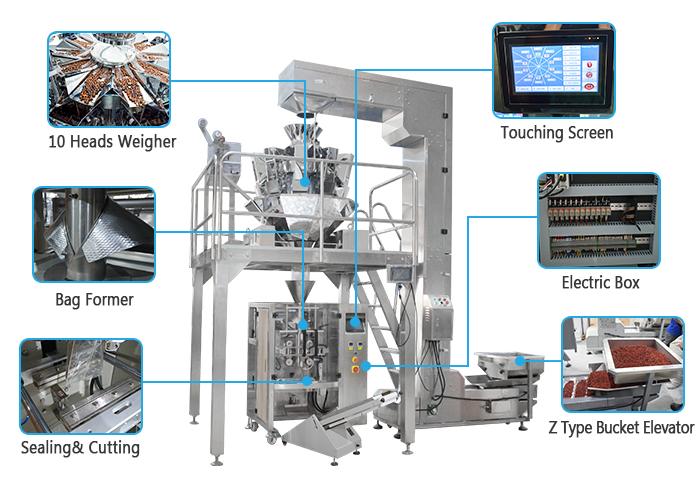

The automatic pouch filling and sealing machine is an essential solution for manufacturers aiming to combine high efficiency with consistent packaging quality. Unlike manual or semi-automatic systems, DBAO’s automatic models are designed to handle every step of the process seamlessly—accurately filling pouches with product and sealing them securely for optimal freshness and presentation. Built with advanced PLC controls, servo-driven mechanisms, and premium sealing technology, these machines deliver unmatched speed, precision, and reliability in modern production lines.

One of the key advantages of our automatic pouch filling and sealing machines is their versatility. They can handle a wide range of pouch types, from zipper and stand-up pouches to spout bags and flat pouches, adapting effortlessly to diverse industries. Whether packaging powders, liquids, granules, sauces, or frozen goods, the machine ensures consistent output and minimizes product loss. Designed with user-friendly interfaces, quick changeover capabilities, and a compact footprint, DBAO’s solutions help businesses increase production capacity, reduce labor costs, and maintain superior packaging integrity.

Applications

DBAO’s automatic pouch filling and sealing machines are widely used in:

- Food Packaging – Candy, nuts, grains, puffed snacks, sauces, frozen vegetables, and ready meals.

- Beverages & Liquids – Dairy products, juices, condiments, and liquid supplements.

- Pharmaceutical & Healthcare – Powders, tablets, herbal products, and dietary supplements.

- Pet Food – Dry kibble, moist treats, and nutritional products.

- Chemicals & Household Products – Fertilizers, detergents, and cleaning supplies.

Why Choose DBAO Packaging Machinery?

- Experience – 14+ years of expertise in packaging machinery design and manufacturing.

- Technology – Advanced third-generation automation with stable, intelligent performance.

- Customization – Tailor-made solutions to meet your product and pouch requirements.

- Quality – Premium components from leading international suppliers ensure durability.

- Global Reach – 1,500+ machines in operation across more than 70 countries.

- Comprehensive Line – Additional solutions available, including labeling systems, nitrogen generators, and check weighers.

- Customer Support – 24/7 technical assistance, spare parts supply, and training services.

- Innovation – Continuous R&D investment keeps machines efficient, eco-friendly, and future-ready.