Mechanical Parameter

|

Model |

DB-8200 |

|

Size (Bag Width) |

70–200 mm |

|

Filling Range |

10–1000 g |

|

Packing Speed |

40–60 bags/min (varies by filling) |

|

Average Precision |

≤ ±1% |

|

Total Power |

2.5 KW |

|

Dimensions (L×W×H) |

1900 × 1570 × 1700 mm |

|

Workflow |

Bag giving → Coding → Opening → Filling 1 → Filling 2 → Auxiliary → Exhaust → Sealing |

|

Applicable Materials

|

1. Block Materials

|

|

2. Granular Materials

|

|

|

3. Powder Materials

|

|

|

4. Liquid/Paste Materials

|

|

|

5. Pickled Products

|

|

|

6. Other Bagging Materials

|

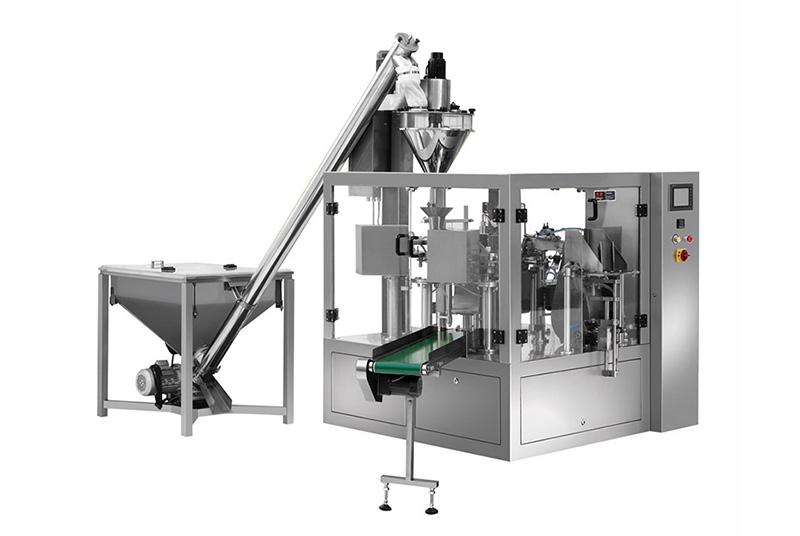

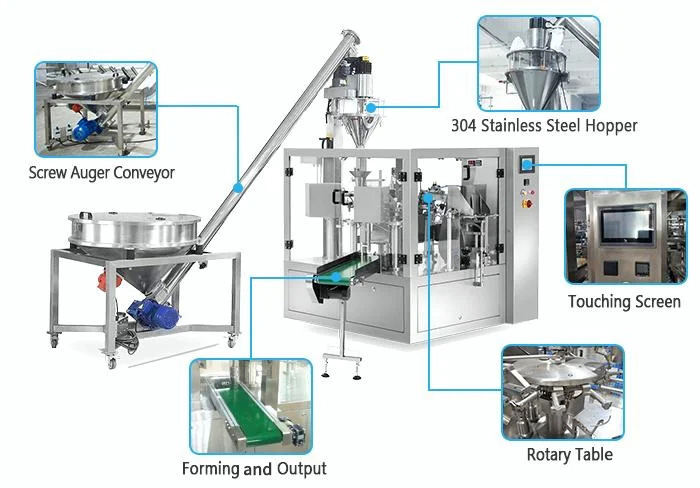

As packaging demands grow more complex, manufacturers are seeking solutions that deliver both speed and precision without compromising flexibility. Vertical packaging machines are designed to meet these challenges head-on, combining forming, filling, and sealing into a streamlined process that maximizes productivity. Unlike traditional methods, vertical packaging optimizes floor space, simplifies operations, and significantly reduces labor costs while maintaining exceptional packaging quality.

DBAO’s vertical packaging solutions stand out for their advanced engineering and intelligent control systems. Built with servo-driven technology and premium components, these machines ensure consistent accuracy in filling and sealing across a wide range of products—from fine powders and liquids to snacks and frozen items. Their modular structure allows for quick format changeovers, making it easy to adapt to shifting product lines or seasonal demands.

Key Features

- Integrated Efficiency – Combines bag forming, filling, and sealing in one continuous cycle.

- Versatile Formats – Handles pillow bags, gusseted bags, quad seals, and more.

- High-Speed Operation – Designed to maintain accuracy even at large production volumes.

- Precision Dosing – Advanced control systems guarantee consistent product weights.

- Hygienic Design – Food-grade materials and easy-clean construction.

- Space-Saving – Vertical structure reduces factory footprint requirements.

- Easy Control – Touchscreen HMI and smart diagnostics for operator convenience.

- Durable Build – Premium components ensure long-term stability and low maintenance.

Why Choose DBAO Packaging Machinery?

- Expertise – 14+ years of dedicated experience in packaging technology.

- Innovation – Advanced servo-driven automation and precision engineering.

- Customization – Tailor-made solutions to match your unique product requirements.

- Reliability – Built with globally recognized components for consistent performance.

- Global Trust – 1,500+ machines operating successfully in over 70 countries.

- Complete Solutions – From packaging machines to auxiliary systems like labeling, check-weighing, and nitrogen flushing.

- Support – Professional technical service, operator training, and responsive after-sales care.

- Sustainability – Energy-efficient designs reduce waste and environmental impact.