Mechanical Parameter

| Similar Mainframe Model Specifications (Product Size Selection Models) | |||||

| Type | DB-420 | DB-520 | DB-720 | DB-900 | DB-1200 |

Film Width | Max. 420 mm | Max. 520 mm | Max. 720 mm | Max. 900 mm | Max. 1200 mm |

Bag Length | 80-300 mm | 80-350 mm | 180-350 mm | 100-600 mm | 100-1000 mm |

Bag Width | 60-200 mm | 100-250 mm | 100-500 mm | 260-430 mm | 290-580 mm |

Film Roll Diameter | Max. 320 mm | Max. 320 mm | Max. 320 mm | Max. 400 mm | Max. 400 mm |

Packaging Rate | 5-60 Bags/Min | 5-60 Bags/Min | 5-55 Bags/Min | 5-20 Bags/Min | 5-20 Bags/Min |

Power | 220V 50/60 Hz, 2 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 4.5 kW | 220V 50/60 Hz, 5 kW |

Measurement Range | 150-1500 ml | 2000 ml | 4000 ml | 1-25 ml | 1.5-45 ml |

Film Thickness | 0.04-0.08 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm |

Machine Size (LxWxH) | 1217x1015x1343 mm | 1488x1080x1490 mm | 1780x1350x2050 mm | 2305x1686x2725 mm | 2900x2050x3500 mm |

Weight | About 650 KG | About 680 KG | About 750 KG | ||

Certification | CE/SGS/ISO Certification | ||||

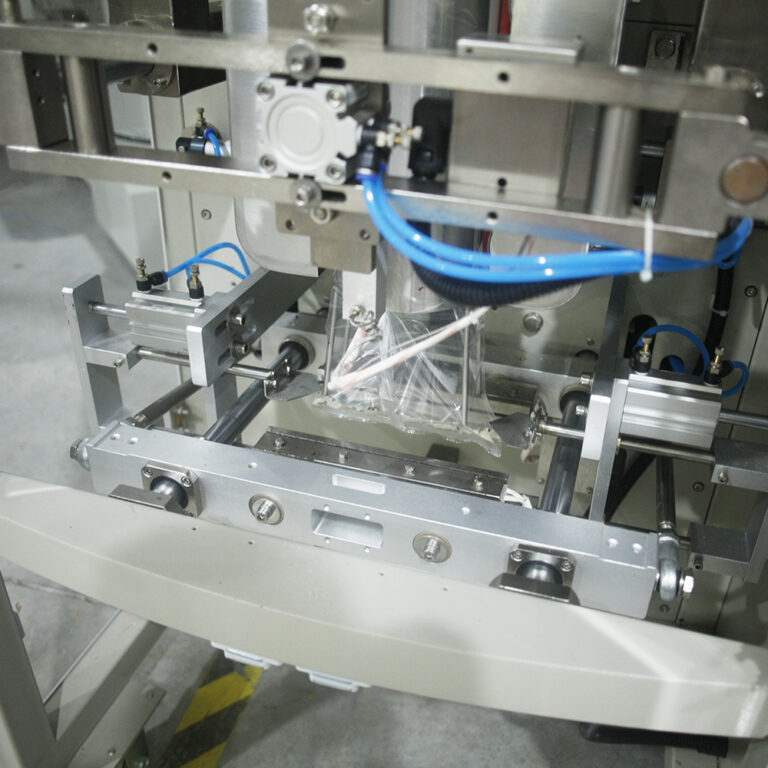

Industrial packaging machines are critical for businesses aiming to streamline large-scale production while maintaining consistent quality and efficiency. DBAO’s industrial packaging solutions are engineered with advanced servo-driven systems, intelligent PLC controls, and premium mechanical components to provide precise, reliable, and high-speed packaging operations. These machines are designed to handle a wide range of products—from powders, granules, and liquids to solids, snacks, and frozen items—ensuring accurate dosing, robust sealing, and consistent output in every cycle.

DBAO industrial packaging machines stand out for their versatility and adaptability. They support multiple packaging formats, including pillow bags, stand-up pouches, quad-seal bags, and stickpacks, allowing manufacturers to quickly switch between products without compromising efficiency. The machines feature modular construction for easy maintenance, hygienic design for compliance with industry standards, and user-friendly interfaces for seamless operation.

Key Features

- High-Precision Operation – Accurate dosing and consistent packaging for powders, liquids, granules, and solids.

- Fully Automated Workflow – Integrates forming, filling, and sealing in one continuous process.

- Versatile Packaging Compatibility – Supports pillow bags, stand-up pouches, quad-seal bags, stickpacks, and more.

- High-Speed Production – Designed for large-scale operations without compromising accuracy.

- Durable Construction – Built with premium international components for long-term reliability.

- Hygienic Design – Easy-to-clean materials and surfaces, meeting food and pharmaceutical safety standards.

- User-Friendly Control – Intuitive touchscreen interface with customizable settings.

- Minimal Maintenance – Modular structure ensures fast service and reduced downtime.

Why Choose DBAO Packaging Machinery?

- Proven Expertise – Over 14 years specializing in designing and manufacturing industrial packaging machines.

- Advanced Automation – High-speed servo-driven systems with intelligent PLC controls ensure precise and stable operation.

- Customizable Solutions – Tailored machines to fit specific product types, packaging formats, and production capacities.

- Premium Components – International-grade parts for long-term durability and reliability.

- Global Reach – 1,500+ machines successfully operating in over 70 countries.

- Complete Packaging Lines – Including auxiliary equipment such as check weighers, labeling systems, and nitrogen generators.

- Professional Support – 24/7 technical assistance, spare parts supply, and operator training.

- Continuous Innovation – Ongoing R&D to improve efficiency, sustainability, and adaptability to industry needs.