Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | ||

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Machine Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

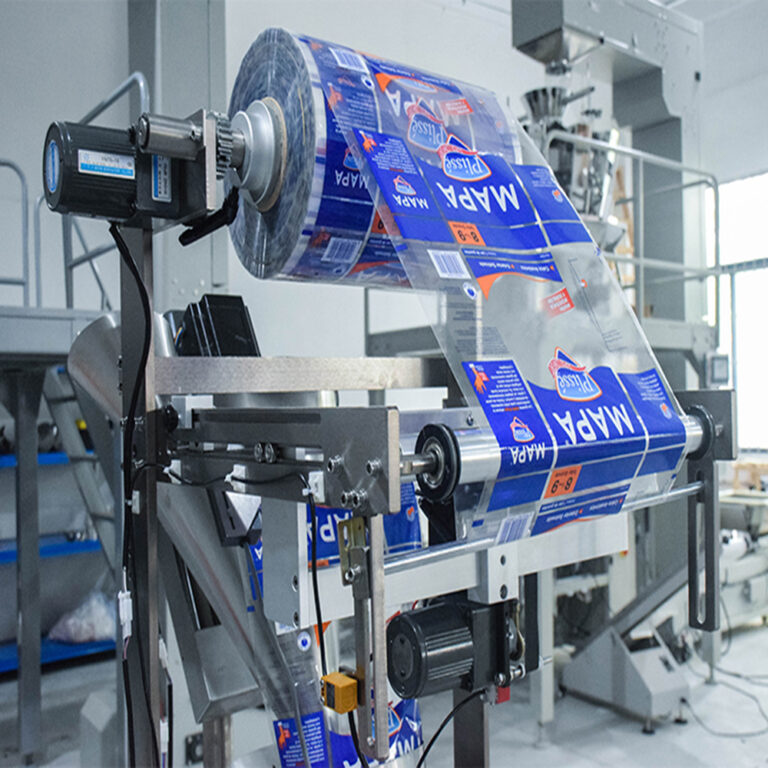

In today’s fast-paced production environment, efficiency, consistency, and reliability are key. Form fill seal packaging (FFS) machines by DBAO are designed to meet these demands by automating every stage of the packaging process—forming bags from roll stock, accurately filling products, and securely sealing packages in one continuous workflow. This integration not only reduces labor costs and human error but also ensures a higher level of productivity and consistency across packaging lines.

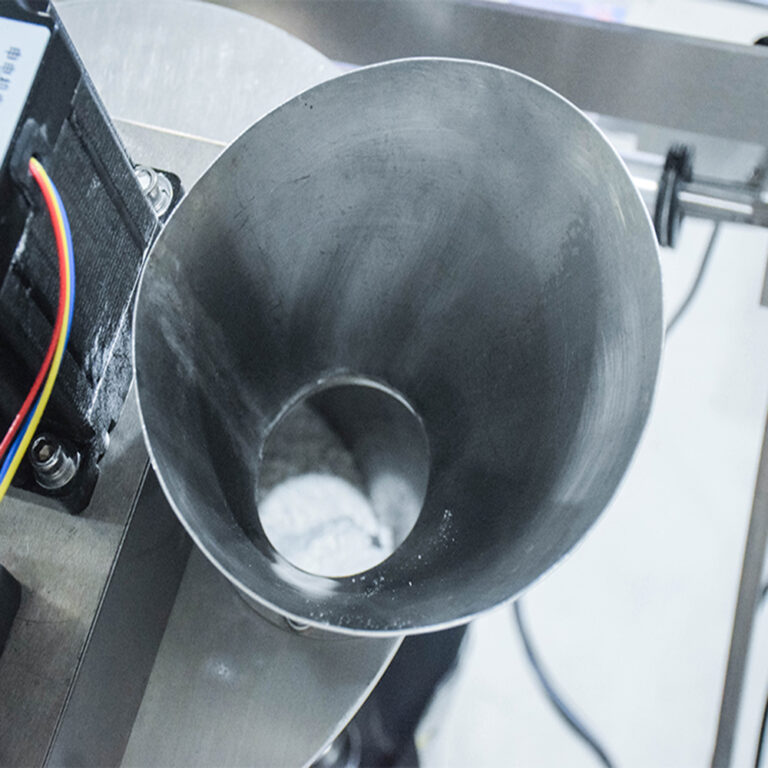

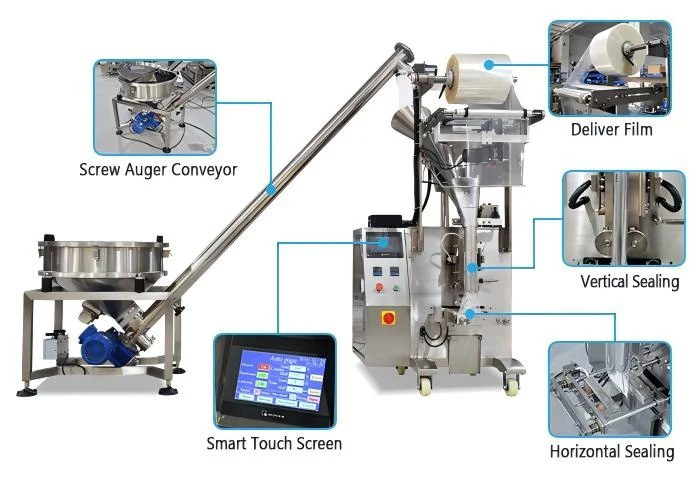

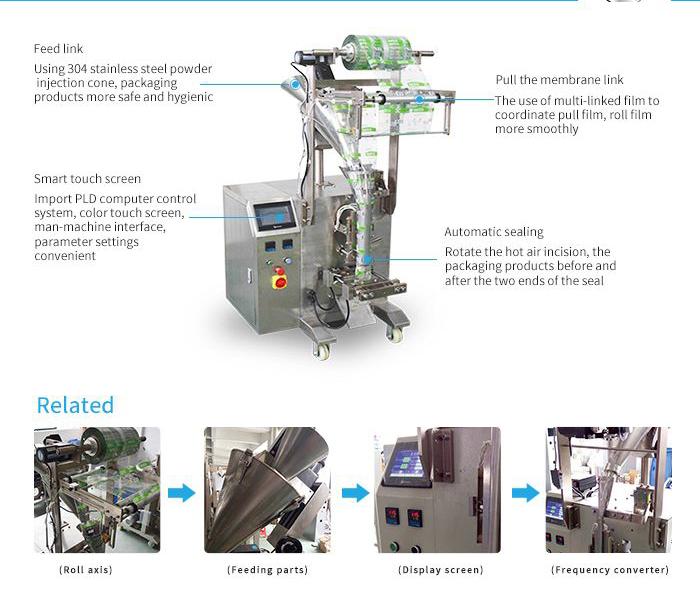

DBAO’s form fill seal packaging equipment is engineered with cutting-edge PLC controls, servo-driven systems, and intelligent sensors that guarantee precision in weighing, filling, and sealing. Built with durable stainless steel structures and easy-to-clean surfaces, these machines meet the strictest hygiene and safety standards required in industries like food, pharmaceuticals, chemicals, and consumer goods.

Key Features

- Fully Automated Workflow – Integrates forming, filling, and sealing into one continuous system.

- High-Speed Performance – Optimized for maximum output with minimal downtime.

- Versatile Product Handling – Suitable for powders, granules, liquids, and solids.

- Flexible Packaging Options – Supports pillow bags, gusset bags, quad-seal, and more.

- Advanced Control System – PLC with touchscreen interface for intuitive operation.

- Precision Weighing & Filling – Ensures accurate dosage and minimal product waste.

- Durable Sealing Technology – Guarantees airtight, tamper-proof packaging.

- Hygienic & Easy to Clean – Stainless steel design meets food safety standards.

- Compact & Efficient Design – Saves factory floor space while delivering powerful performance.

Why Choose DBAO Packaging Machinery?

- Proven Expertise – Over 14 years of innovation in packaging machinery.

- Customizable Solutions – Machines tailored to fit unique industry and product needs.

- Reliable Performance – High-quality international components for durability.

- Global Experience – Installed in 70+ countries with strong client trust.

- Complete Packaging Lines – Integrated solutions including conveyors, labeling, and inspection systems.

- 24/7 Technical Support – Professional service team providing training, spare parts, and maintenance.

- Efficiency & ROI – Designed to maximize productivity and reduce operational costs.