Mechanical Parameter

| Similar Mainframe Model Specifications (Product Size Selection Models) | |||||

| Type | DB-420 | DB-520 | DB-720 | DB-900 | DB-1200 |

Film Width | Max. 420 mm | Max. 520 mm | Max. 720 mm | Max. 900 mm | Max. 1200 mm |

Bag Length | 80-300 mm | 80-350 mm | 180-350 mm | 100-600 mm | 100-1000 mm |

Bag Width | 60-200 mm | 100-250 mm | 100-500 mm | 260-430 mm | 290-580 mm |

Film Roll Diameter | Max. 320 mm | Max. 320 mm | Max. 320 mm | Max. 400 mm | Max. 400 mm |

Packaging Rate | 5-60 Bags/Min | 5-60 Bags/Min | 5-55 Bags/Min | 5-20 Bags/Min | 5-20 Bags/Min |

Power | 220V 50/60 Hz, 2 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 4.5 kW | 220V 50/60 Hz, 5 kW |

Measurement Range | 150-1500 ml | 2000 ml | 4000 ml | 1-25 ml | 1.5-45 ml |

Film Thickness | 0.04-0.08 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm |

Machine Size (LxWxH) | 1217x1015x1343 mm | 1488x1080x1490 mm | 1780x1350x2050 mm | 2305x1686x2725 mm | 2900x2050x3500 mm |

Weight | About 650 KG | About 680 KG | About 750 KG | ||

Certification | CE/SGS/ISO Certification | ||||

In today’s competitive production environment, efficiency, accuracy, and adaptability are the benchmarks of successful packaging operations. A bag filling and sealing machine from DBAO Packaging Machinery delivers exactly that—combining advanced automation with robust engineering to meet the demands of modern industries.

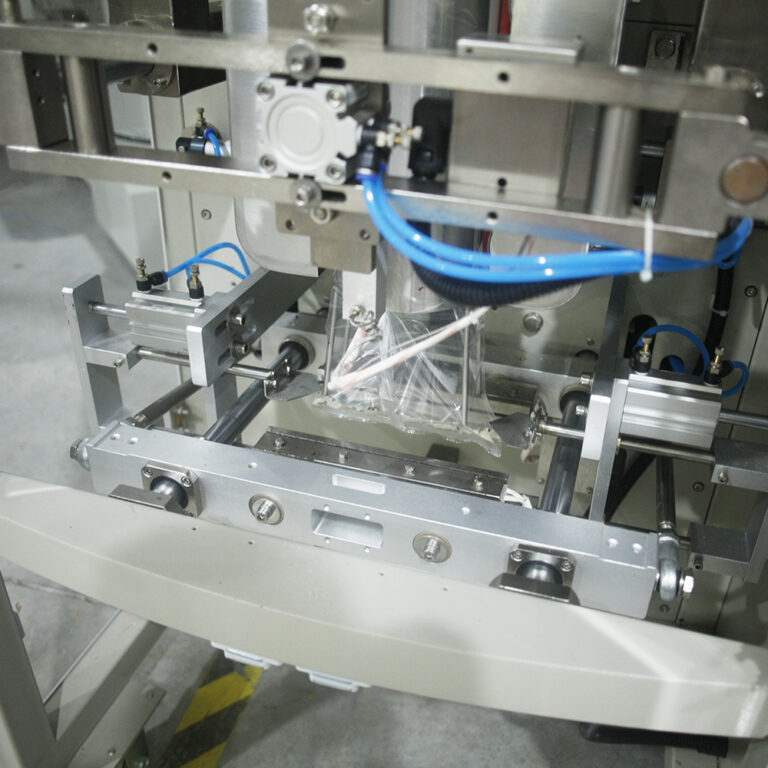

Our machines are built to streamline the packaging process by integrating filling and sealing into one continuous, reliable operation. This not only reduces manual labor but also ensures consistent product quality with every bag. Engineered with servo-driven systems, intelligent PLC controls, and hygienic stainless-steel construction, DBAO’s bag filling and sealing solutions offer unmatched precision and durability.

Key Features

- Precision Filling – Accurate dosing reduces product waste and ensures consistency.

- Integrated Sealing System – Delivers strong, airtight seals to preserve product freshness.

- Flexible Bag Formats – Compatible with pillow, gusseted, flat-bottom, and custom bags.

- High-Speed Automation – Boosts production capacity with stable performance.

- User-Friendly Controls – Intuitive PLC and touchscreen operation for simplified use.

- Hygienic & Durable Design – Stainless-steel build for food, pharma, and clean environments.

- Energy-Efficient Operation – Designed to lower long-term running costs.

- Low Maintenance – Built with high-quality components for extended service life.

Why Choose DBAO Packaging Machinery?

- Proven Expertise – Years of industry experience with a strong reputation worldwide.

- Customized Solutions – Machines tailored to your specific production requirements.

- Quality Engineering – Built with international-standard components for long-term use.

- Global Presence – Trusted by clients in over 70 countries.

- Comprehensive Support – From installation to training, maintenance, and spare parts.

- Turnkey Systems – Complete packaging lines designed for end-to-end efficiency.

- Return on Investment – Designed to improve throughput while minimizing costs.