Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | 35–70 Bags/Min | 35–70 Bags/Min |

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Machine Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

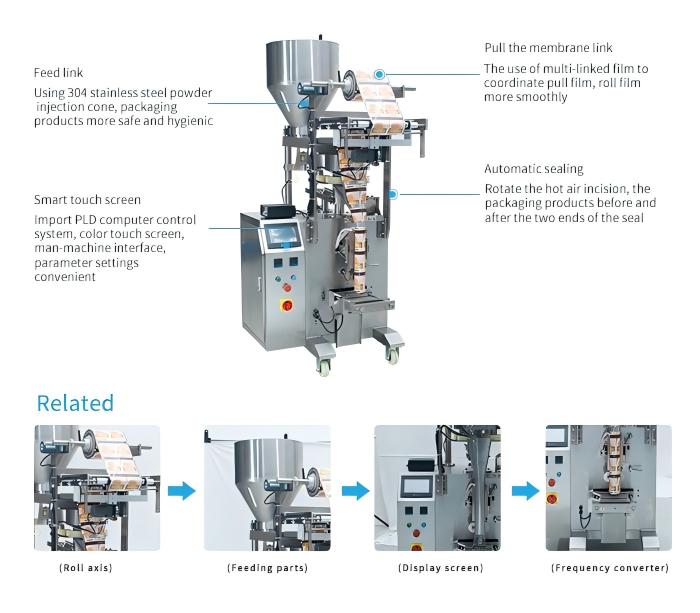

In today’s fast-paced manufacturing environment, efficiency and accuracy are no longer optional—they are essential. DBAO’s packaging automation solutions are engineered to help companies meet increasing market demands while ensuring consistent product quality. By integrating intelligent controls, servo-driven technology, and modular machine design, our systems provide end-to-end automation for forming, filling, sealing, and secondary packaging processes.

Unlike conventional equipment, DBAO machines are built with adaptability in mind. They can handle a wide range of packaging materials and product types—from powders and liquids to granules and ready-to-eat items—without compromising on performance. Quick changeovers and user-friendly PLC interfaces make operation simple, while robust construction and premium components guarantee long-lasting durability.

Key Features

- Integrated Automation – One-stop solution for forming, filling, sealing, and secondary packaging.

- High Efficiency – Optimized throughput with minimal downtime.

- Flexible Configurations – Adaptable to powders, liquids, granules, and solid products.

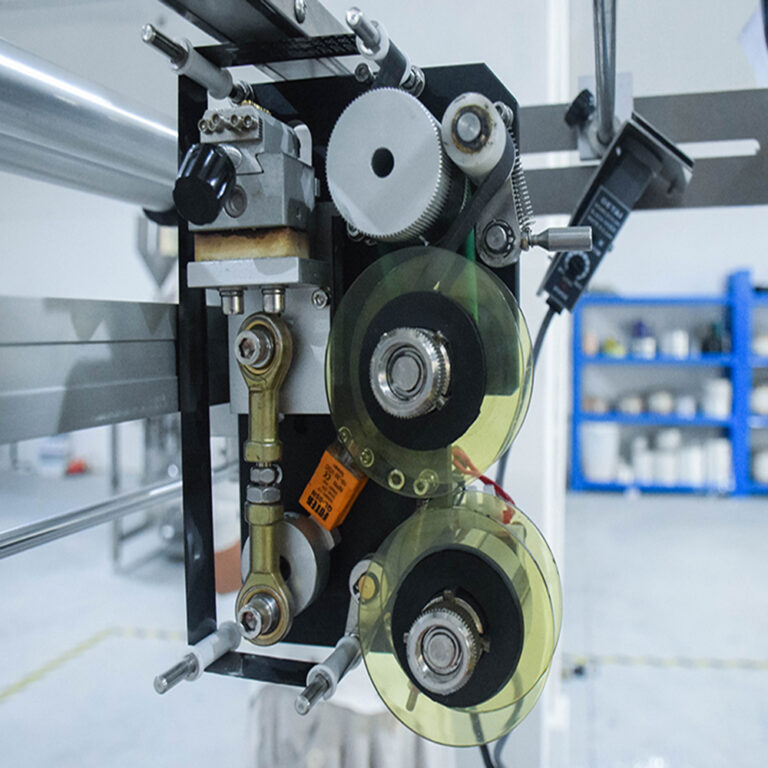

- Precision Engineering – Accurate dosing and sealing for consistent packaging quality.

- User-Friendly Operation – Intuitive PLC control with smart touchscreen interface.

- Quick Changeovers – Fast adjustments for different bag types and sizes.

- Durable Build – Heavy-duty construction with high-quality electrical components.

- Hygiene Compliance – Stainless steel design meeting food and pharmaceutical standards.

Applications

DBAO’s packaging automation solutions are widely applied across industries, including:

- Food & Beverage – Snacks, sauces, coffee, frozen foods, condiments.

- Pharmaceutical & Healthcare – Powders, supplements, tablets, oral liquids.

- Cosmetics & Personal Care – Creams, lotions, shampoo, single-use packs.

- Chemical & Household Products – Detergents, cleaning agents, and granular products.