Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | ||

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

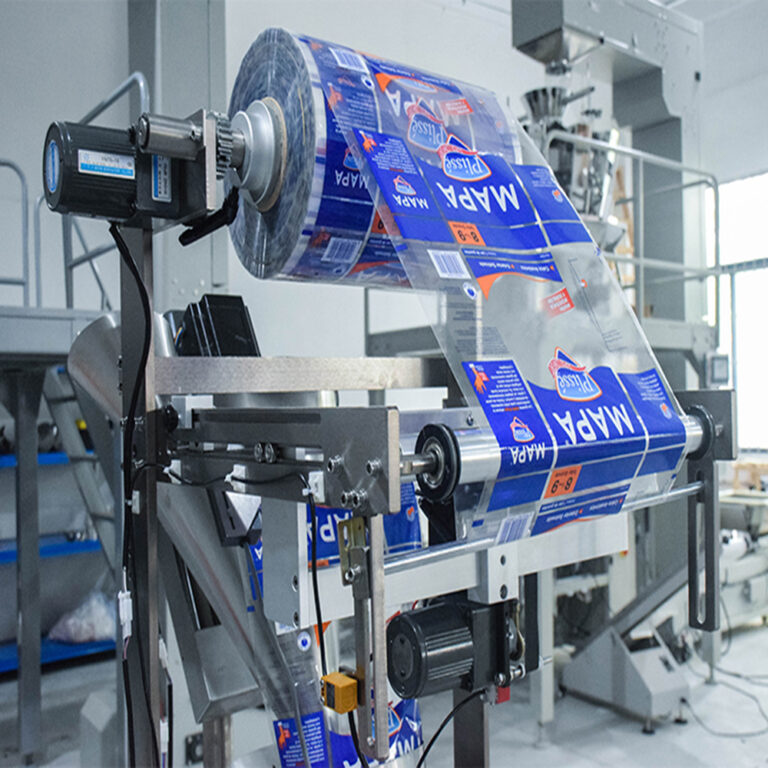

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Machine Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

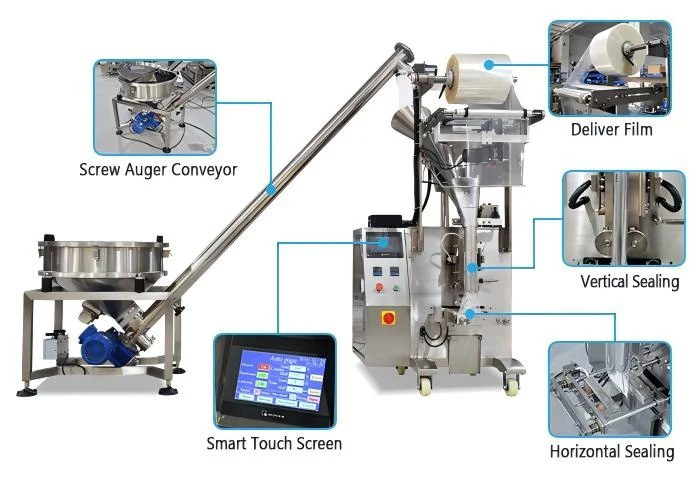

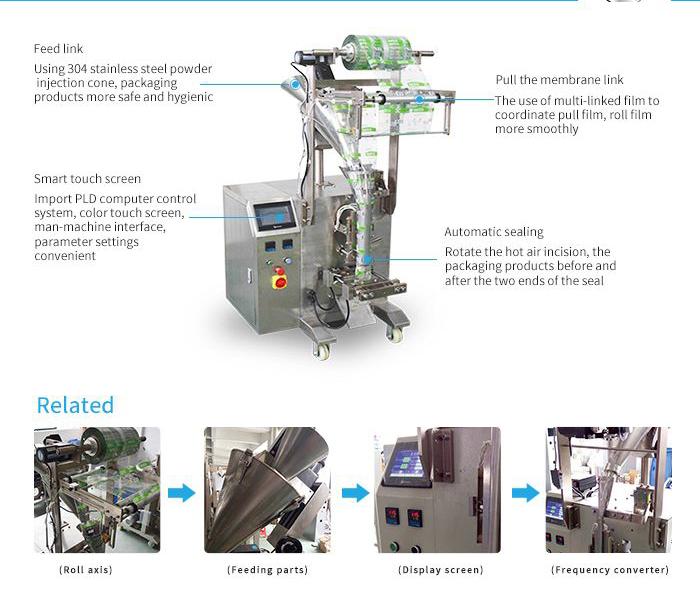

As manufacturing industries continue to evolve, businesses are turning to smarter, faster, and more reliable technologies to stay competitive. DBAO’s automated packaging equipment is designed to meet these modern production demands with advanced engineering, intelligent controls, and robust construction. By streamlining every stage of packaging—from product feeding and dosing to bag forming, filling, and sealing—our systems help manufacturers achieve higher efficiency with fewer resources.

Each machine is built with versatility at its core, capable of handling diverse packaging formats, including sachets, pouches, stick packs, and gusset bags. High-speed servo-driven components ensure precision filling and sealing, while intuitive PLC touchscreens make operation simple, even for less-experienced operators. Quick changeovers reduce downtime, and hygienic stainless-steel design ensures compliance with stringent food and pharmaceutical standards.

Key Features

- Complete Automation – End-to-end solution for filling, sealing, and packaging.

- High-Speed Output – Optimized for continuous, large-scale production.

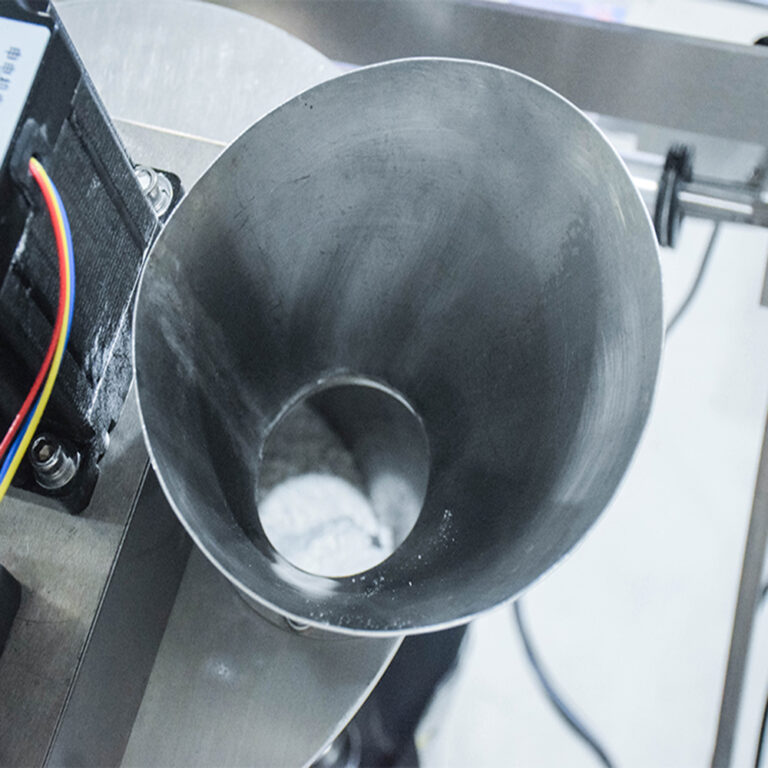

- Precision Filling – Accurate dosing for powders, liquids, pastes, and granules.

- Versatile Formats – Supports a wide range of bag and pouch types.

- User-Friendly Operation – Smart PLC interface with easy-to-use controls.

- Durability – Premium-grade components ensure long-lasting stability.

- Quick Changeover – Fast adjustments for different products or packaging sizes.

- Hygienic Design – Stainless steel construction suitable for food and pharma industries.

Why Choose DBAO Packaging Machinery?

- Proven Experience – 14+ years of expertise in packaging automation.

- Advanced Technology – Intelligent systems designed for modern manufacturing.

- Global Trust – Over 1,500 machines operating successfully in 70+ countries.

- Tailored Solutions – OEM and ODM options to match unique production needs.

- Efficiency Focused – Increased output with reduced labor and material waste.

- Reliable Components – Built with international electrical and mechanical brands.

- Comprehensive Support – From installation to after-sales service, we ensure smooth operations.

- Future-Ready – Scalable equipment that evolves with your production goals.