Mechanical Parameter

| Similar Mainframe Model Specifications (Product Size Selection Models) | |||||

| Type | DB-420 | DB-520 | DB-720 | DB-900 | DB-1200 |

Film Width | Max. 420 mm | Max. 520 mm | Max. 720 mm | Max. 900 mm | Max. 1200 mm |

Bag Length | 80-300 mm | 80-350 mm | 180-350 mm | 100-600 mm | 100-1000 mm |

Bag Width | 60-200 mm | 100-250 mm | 100-500 mm | 260-430 mm | 290-580 mm |

Film Roll Diameter | Max. 320 mm | Max. 320 mm | Max. 320 mm | Max. 400 mm | Max. 400 mm |

Packaging Rate | 5-60 Bags/Min | 5-60 Bags/Min | 5-55 Bags/Min | 5-20 Bags/Min | 5-20 Bags/Min |

Power | 220V 50/60 Hz, 2 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 4.5 kW | 220V 50/60 Hz, 5 kW |

Measurement Range | 150-1500 ml | 2000 ml | 4000 ml | 1-25 ml | 1.5-45 ml |

Film Thickness | 0.04-0.08 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm |

Machine Size (LxWxH) | 1217x1015x1343 mm | 1488x1080x1490 mm | 1780x1350x2050 mm | 2305x1686x2725 mm | 2900x2050x3500 mm |

Weight | About 650 KG | About 680 KG | About 750 KG | ||

Certification | CE/SGS/ISO Certification | ||||

In today’s competitive market, businesses demand packaging solutions that adapt quickly to diverse products without compromising quality or efficiency. A flexible packaging machine from DBAO delivers exactly that—combining advanced automation, precision engineering, and adaptability in a single system. Unlike conventional packaging setups that limit production to one format, DBAO’s flexible machines are engineered to handle a wide variety of bag styles, product consistencies, and packaging materials.

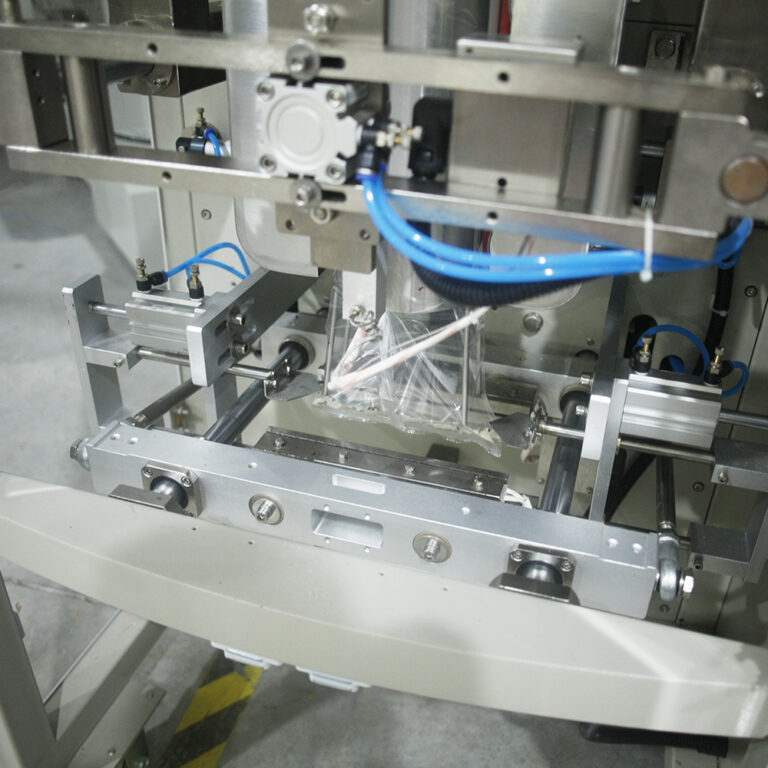

Whether you’re packaging dry goods, powders, granules, liquids, or viscous products, this system offers seamless changeovers and customizable options to match your requirements. The compact yet robust structure ensures it fits efficiently into both small workshops and large-scale production facilities. Equipped with intelligent PLC controls and intuitive user interfaces, operators can easily manage speed, bag size, and sealing strength, reducing setup times and minimizing downtime.

Key Features

- Versatile Functionality – Handles powders, liquids, granules, pastes, and solids.

- Adaptable Bag Styles – Supports pouches, pillow bags, gusseted bags, and more.

- Precision Sealing – Guarantees secure, airtight closures for product freshness.

- High-Speed Operation – Designed for continuous, large-volume production.

- Easy-to-Use Interface – Smart PLC control system with touch-screen operation.

- Durable Build – Stainless-steel construction for hygiene and long service life.

- Quick Changeovers – Rapid adjustment for various products and packaging sizes.

- Energy Efficient – Optimized design to reduce power consumption.

Why Partner with DBAO Packaging Machinery?

- Extensive Experience – Over 14 years specializing in automated packaging technology.

- Worldwide Reach – Trusted by clients in 70+ countries.

- Tailored Engineering – OEM/ODM customization for unique production needs.

- Reliable Systems – Built for continuous, high-volume operation.

- Lower Costs – Reduce labor, energy, and material waste.

- Premium Quality Components – Equipped with globally recognized parts.

- Comprehensive Support – From installation to after-sales service.

- Scalable Solutions – Machines designed to grow with your business.