Mechanical Parameter

Model | DB-8200 |

Size (Bag Width) | 70–200 mm |

Filling Range | 10–1000 g |

Packing Speed | 40–60 bags/min (varies by filling) |

Average Precision | ≤ ±1% |

Total Power | 2.5 KW |

Dimensions (L×W×H) | 1900 × 1570 × 1700 mm |

Workflow | Bag giving → Coding → Opening → Filling 1 → Filling 2 → Auxiliary → Exhaust → Sealing |

Applicable Materials

| Block Materials

|

Granular Materials

| |

Powder Materials

| |

Liquid/Paste Materials

| |

Pickled Products

| |

Other Bagging Materials

|

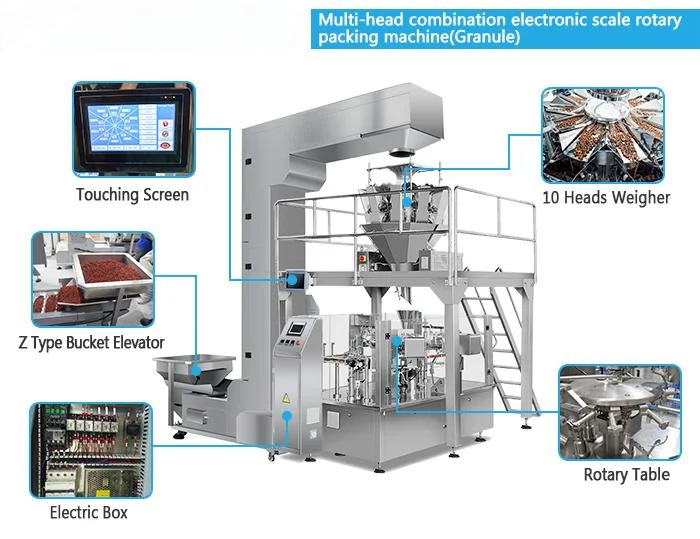

When it comes to modern packaging, businesses demand machines that combine accuracy, durability, and efficiency. DBAO’s form fill machine is engineered to meet these exact needs, offering manufacturers a powerful solution to streamline operations and ensure consistent, high-quality packaging results. Built with advanced automation and intelligent controls, this equipment forms, fills, and seals bags in a single seamless process—minimizing manual intervention while maximizing output.

One of the biggest advantages of the DBAO form fill machine is its adaptability. Whether you are packaging granular products, powders, liquids, or small items, the system can be customized to handle various packaging formats with ease. Its robust stainless-steel frame ensures long-lasting performance, while high-precision servo motors and PLC controls provide unmatched accuracy and reliability.

Key Features

- High-Speed Automation – Simultaneous forming, filling, and sealing for faster throughput.

- Precision Control – Servo-driven system ensures accurate weights and measurements.

- Versatile Packaging – Handles powders, liquids, granules, and solid products.

- Durable Construction – Built with premium-grade stainless steel for longevity.

- User-Friendly Interface – Intuitive PLC touchscreen for easy operation.

- Quick Changeovers – Fast format adjustments for multiple bag styles and sizes.

- Energy Efficiency – Optimized design reduces power consumption and material waste.

- Low Maintenance – Simplified structure with easy cleaning and servicing.

Why Choose DBAO Packaging Machinery?

- Proven Expertise – 14+ years of innovation in packaging machinery.

- Cutting-Edge Engineering – Designed with advanced automation and servo technology.

- Global Trust – Installed in over 70 countries with 1,500+ machines in operation.

- Custom Solutions – OEM/ODM services tailored to your unique product needs.

- Reliable Components – Built with globally recognized electrical parts for stability.

- After-Sales Support – Comprehensive technical assistance and spare parts availability.

- Sustainability Focus – Solutions that minimize waste and maximize efficiency.

- Long-Term Reliability – Machines engineered for continuous industrial performance.