Mechanical Parameter

|

Model |

DBY-4 |

DBY-6 |

DBY-8 |

|

Capacity |

Max. 30 cycles/min |

||

|

Bag Size |

L: 50–180 mm, W: 20–100 mm |

||

|

Film Width & Thickness |

0.05–0.1 mm |

||

|

Cutting Types |

1. Straight Cutting |

||

|

Air & Power |

0.8 Mpa, 0.8 m³/min, 3.5 kW |

0.8 Mpa, 1 m³/min, 4.5 kW |

0.8 Mpa, 1.5 m³/min, 5 kW |

|

Weight |

350 kg |

450 kg |

550 kg |

Efficiency and accuracy are at the core of every successful packaging operation, and DBAO’s vertical form fill solutions are engineered to deliver both. By integrating bag forming, product filling, and sealing into a seamless automated process, these machines significantly cut down manual labor, reduce material waste, and maximize production output. Whether you are packaging fine powders, liquid-based products, or granular materials, our vertical form fill equipment adapts easily to different applications, giving manufacturers a highly versatile and dependable packaging option.

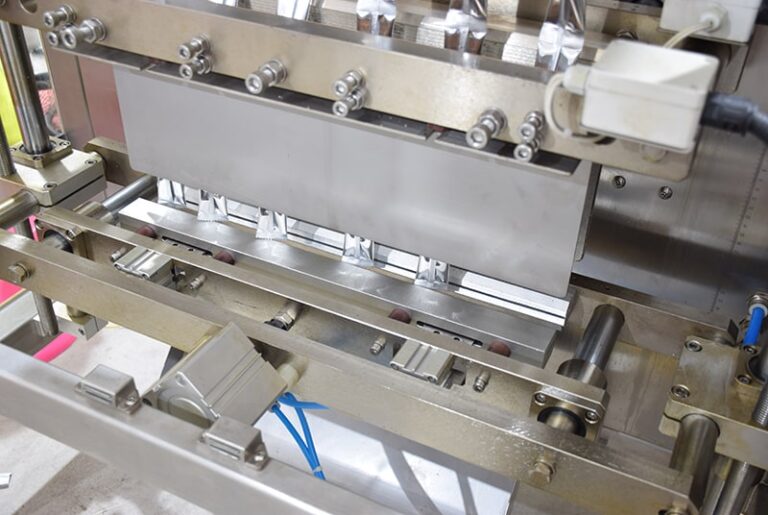

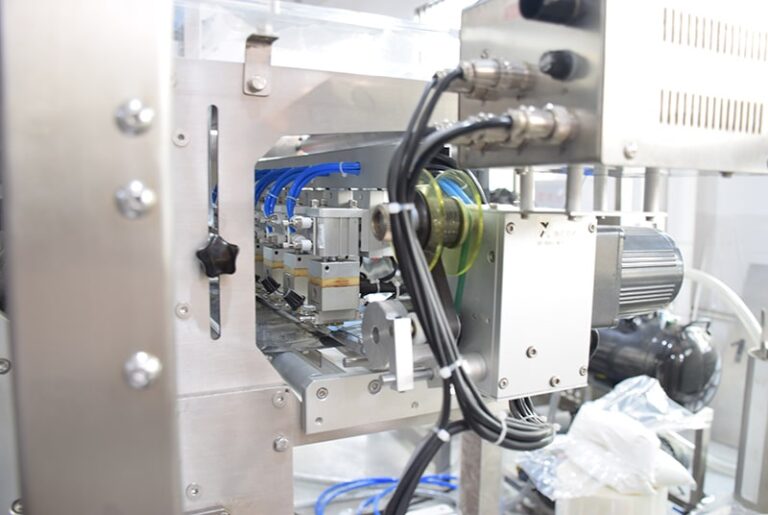

Built with advanced motion control systems and high-precision weighing technology, DBAO’s vertical form fill machines guarantee consistent package integrity and accurate filling for every cycle. The robust stainless-steel design ensures hygiene and durability, making them particularly well-suited for industries where cleanliness and product safety are top priorities. With user-friendly controls, quick-change functionality, and minimal maintenance requirements, our equipment supports businesses looking to scale production without sacrificing quality.

Key Features

- Integrated Packaging Process – Form, fill, and seal functions in one machine.

- Versatile Compatibility – Handles powders, liquids, solids, and granules.

- Advanced Motion Control – Ensures precise filling and sealing.

- Durable Stainless-Steel Build – Ideal for food and pharmaceutical applications.

- Flexible Bag Styles – Supports pillow bags, gusseted bags, and other formats.

- Energy and Cost Efficient – Optimized design reduces material and energy waste.

- Simple Operation – Touchscreen controls with quick-changeover options.

- Low Maintenance – Easy-to-clean components and reliable structure.

Applications

DBAO’s vertical form fill equipment is widely applied in:

- Food & Beverage – Coffee, sugar, rice, snacks, sauces, frozen goods.

- Pharmaceuticals – Medical powders, tablets, small liquid doses.

- Chemicals – Detergents, fertilizers, and industrial powders.

- Agriculture – Seeds, animal feed, and supplements.

- Consumer Goods – Daily essentials like tea, spices, and personal care products.