Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | 35–70 Bags/Min | 35–70 Bags/Min |

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Machine Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

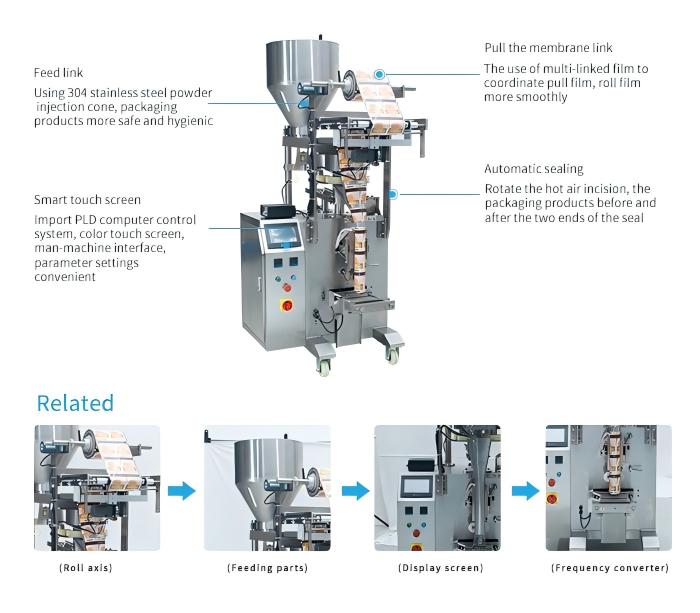

Designed for medium to large snack production lines, this packaging solution improves labor efficiency, reduces material waste, and ensures consistent packaging quality—ideal for businesses seeking higher output, product standardization, and retail-ready presentation.

Why Choose DBAO Packaging Machinery?

Partnering with DBAO PACK means choosing a supplier with proven expertise and global recognition in snack packaging automation.

Advantages of DBAO PACK:

- 14+ Years of R&D and Production Expertise

Specialized in flexible packaging machinery serving over 70 global markets. - Advanced Engineering for Snack Products

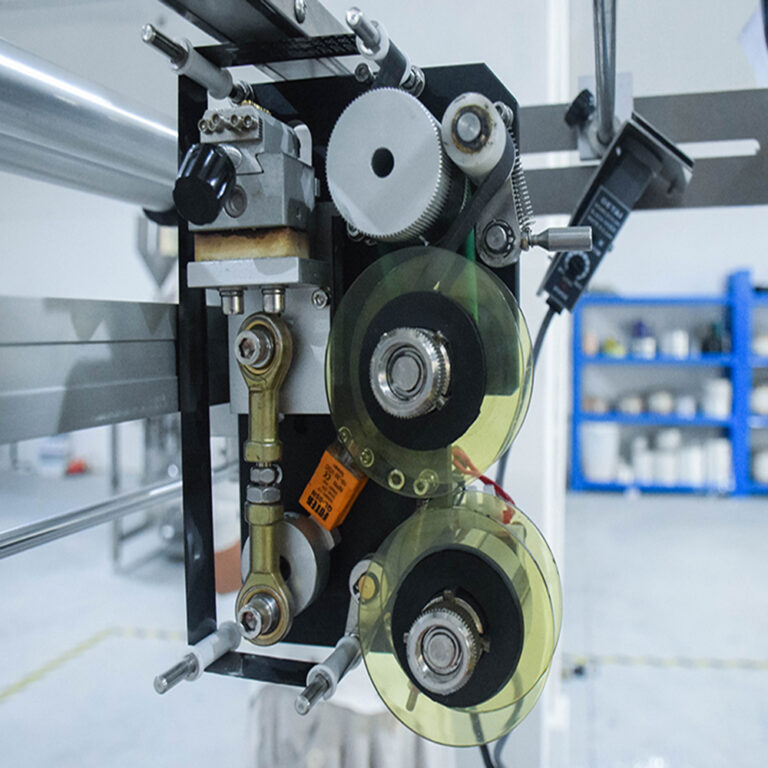

Machine design optimized for fragile and airy materials like popcorn and puffed snacks. - Reliable Electrical & Pneumatic Components

Sourced from internationally trusted suppliers to ensure smooth operation. - Global Service & Technical Support

24/7 professional assistance, remote diagnostics, and fast spare parts supply. - OEM / ODM Customization

Tailor-made solutions to match your desired filling volume, packaging style, and factory layout.

DBAO PACK helps popcorn producers improve packaging quality, reduce product loss, and achieve strong brand presentation at retail.