Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | ||

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

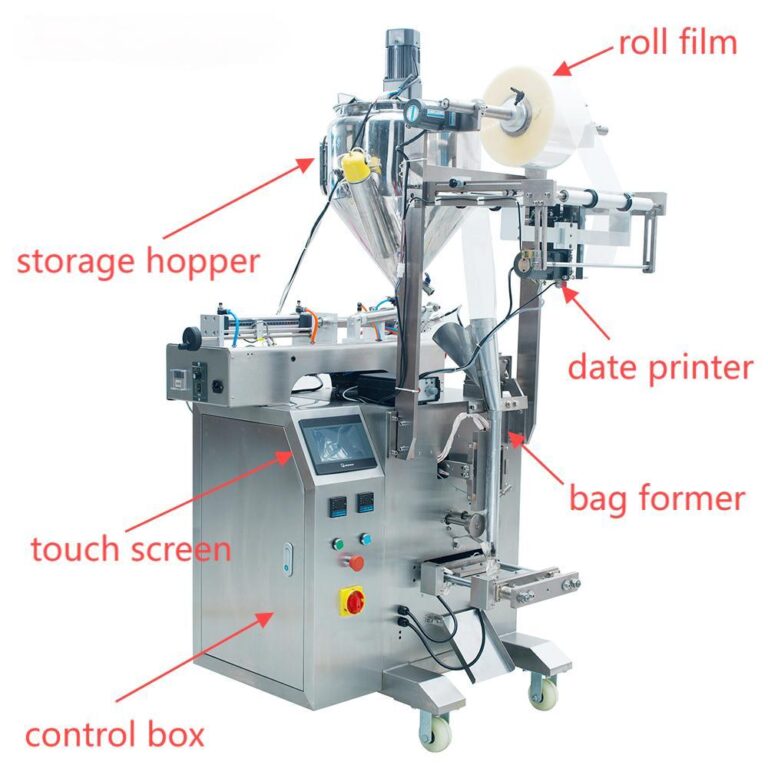

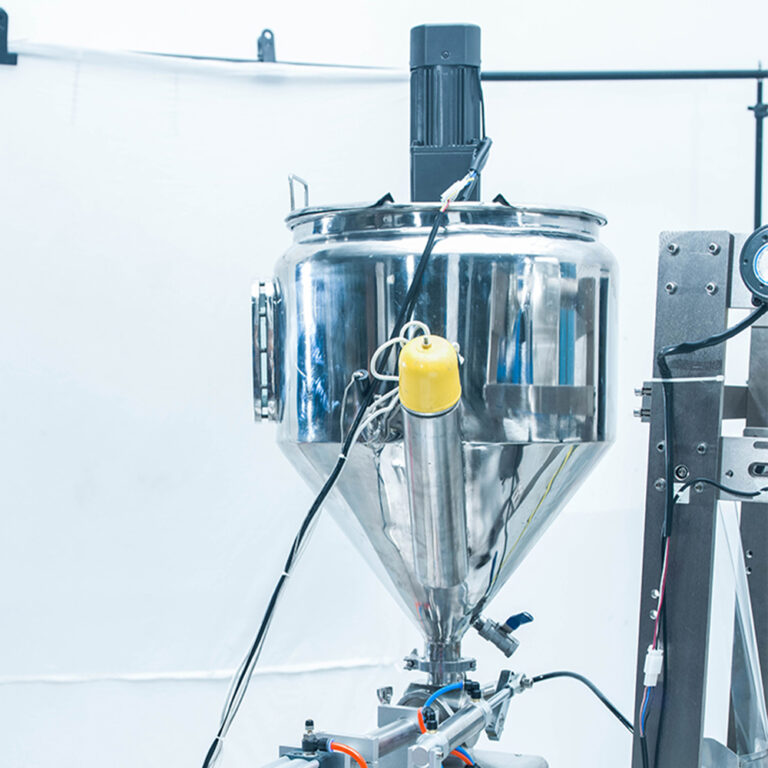

The DBAO Liquid Pouch Packaging Machine is designed to streamline the entire liquid packing process, delivering stable filling accuracy and secure pouch sealing for a wide range of fluid and semi-fluid products. Liquids often vary in viscosity—from thin beverages to thick sauces—and require a packaging system that can manage flow consistency, prevent leakage, and maintain hygiene. Our high-performance solution integrates advanced filling technology with intelligent motion control, ensuring smooth product dosing, clean cut-off, and airtight sealing even under continuous high-speed operation.

Key Features

- High-accuracy liquid dosing system suitable for low and high-viscosity liquids.

- Drip-free filling technology prevents product leakage and pouch contamination.

- Supports various pouch formats including stand-up pouches, spouted pouches, pillow bags, and 3/4-side sealed bags.

- Hygienic stainless-steel construction compliant with food and pharmaceutical standard requirements.

- PLC touch control system with recipe storage for rapid changeovers and easy operation.

- Optional CIP automatic cleaning simplifies maintenance and enhances production safety.

- Compatible auxiliary equipment such as paste feeding pumps, bottle unscramblers, nitrogen injection systems, and labeling units.