Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | 35–70 Bags/Min | 35–70 Bags/Min |

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Machine Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

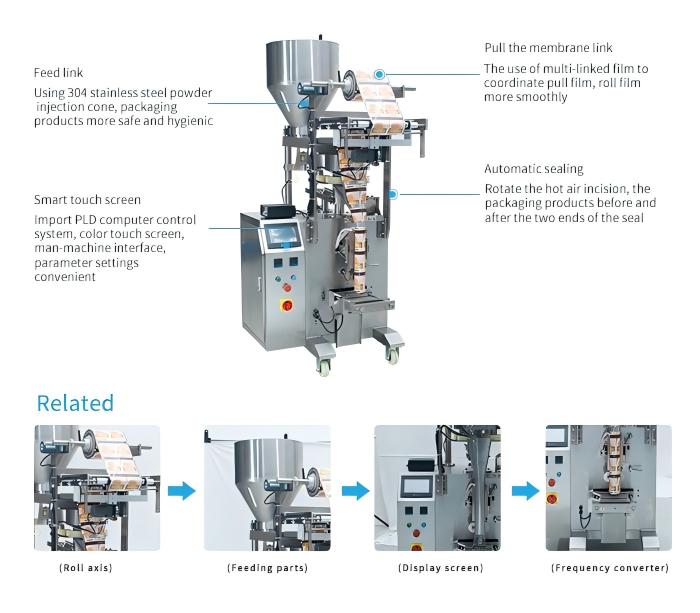

A bag filling machine is an essential solution for manufacturers seeking to improve efficiency, maintain consistency, and reduce labor costs in their packaging process. DBAO’s bag filling machines are engineered to handle a wide variety of products—from powders and granules to liquids and semi-solids—while providing precise filling accuracy and consistent output. These machines combine advanced servo-driven technology with intelligent control systems to streamline the bagging process, ensuring each package meets strict quality and safety standards.

One of the major advantages of DBAO’s bag filling machines is their flexibility. They are compatible with multiple bag types, including pillow bags, gusseted bags, quad-seal bags, and stand-up pouches, allowing manufacturers to adapt quickly to changing product lines or packaging requirements. With features such as airtight sealing, adjustable filling volume, and user-friendly interfaces, these machines ensure minimal waste, enhanced shelf appeal, and improved operational efficiency.

Applications

DBAO bag filling machines are widely used in:

- Food & Beverage – Snacks, nuts, grains, rice, sugar, sauces, frozen foods.

- Pharmaceuticals & Nutraceuticals – Powders, capsules, tablets, and supplements.

- Chemicals & Industrial Products – Fertilizers, detergents, granular chemicals.

- Pet Food – Dry kibble, treats, and animal feed.

- Daily Necessities – Seeds, powders, and household products.

Why Choose DBAO Packaging Machinery?

- Experience – Over 14 years of expertise in packaging machinery design and manufacturing.

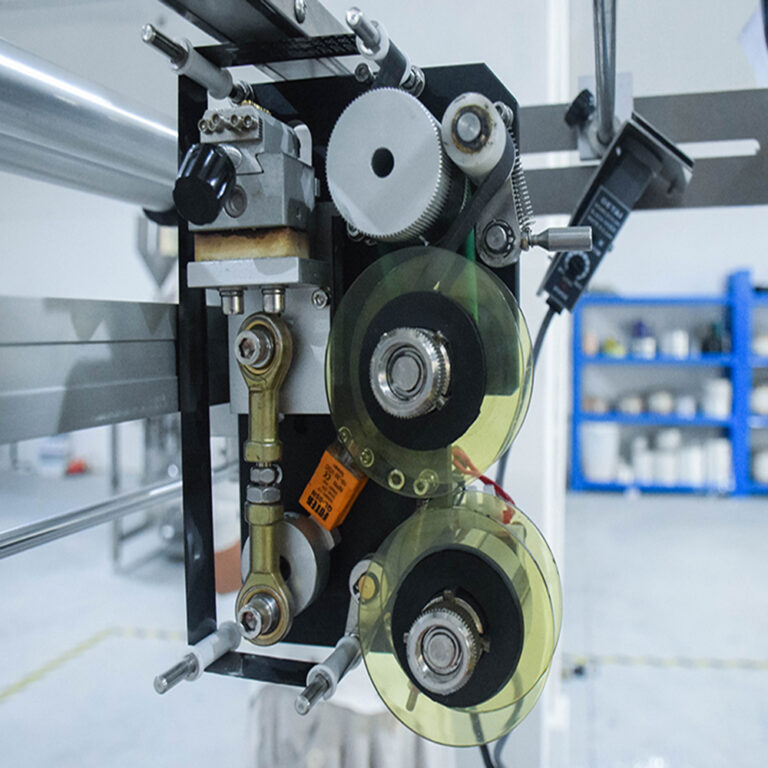

- Advanced Technology – Third-generation servo-driven systems for stable, high-speed performance.

- Customization – Machines tailored to specific product types and bag formats.

- Premium Quality – Internationally recognized components for long-term reliability.

- Global Reach – 1,500+ machines operating in over 70 countries worldwide.

- Complete Solutions – Including auxiliary equipment such as check weighers, labeling systems, and nitrogen generators.

- Professional Support – 24/7 technical assistance, spare parts availability, and operator training.

- Innovation Focused – Continuous R&D investment to improve efficiency, sustainability, and adaptability.