Mechanical Parameter

| Similar Mainframe Model Specifications (Product Size Selection Models) | |||||

| Type | DB-420 | DB-520 | DB-720 | DB-900 | DB-1200 |

Film Width | Max. 420 mm | Max. 520 mm | Max. 720 mm | Max. 900 mm | Max. 1200 mm |

Bag Length | 80-300 mm | 80-350 mm | 180-350 mm | 100-600 mm | 100-1000 mm |

Bag Width | 60-200 mm | 100-250 mm | 100-500 mm | 260-430 mm | 290-580 mm |

Film Roll Diameter | Max. 320 mm | Max. 320 mm | Max. 320 mm | Max. 400 mm | Max. 400 mm |

Packaging Rate | 5-60 Bags/Min | 5-60 Bags/Min | 5-55 Bags/Min | 5-20 Bags/Min | 5-20 Bags/Min |

Power | 220V 50/60 Hz, 2 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 4.5 kW | 220V 50/60 Hz, 5 kW |

Measurement Range | 150-1500 ml | 2000 ml | 4000 ml | 1-25 ml | 1.5-45 ml |

Film Thickness | 0.04-0.08 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm |

Machine Size (LxWxH) | 1217×1015×1343 mm | 1488×1080×1490 mm | 1780×1350×2050 mm | 2305×1686×2725 mm | 2900×2050×3500 mm |

Weight | About 650 KG | About 680 KG | About 750 KG | ||

Certification | CE/SGS/ISO Certification | ||||

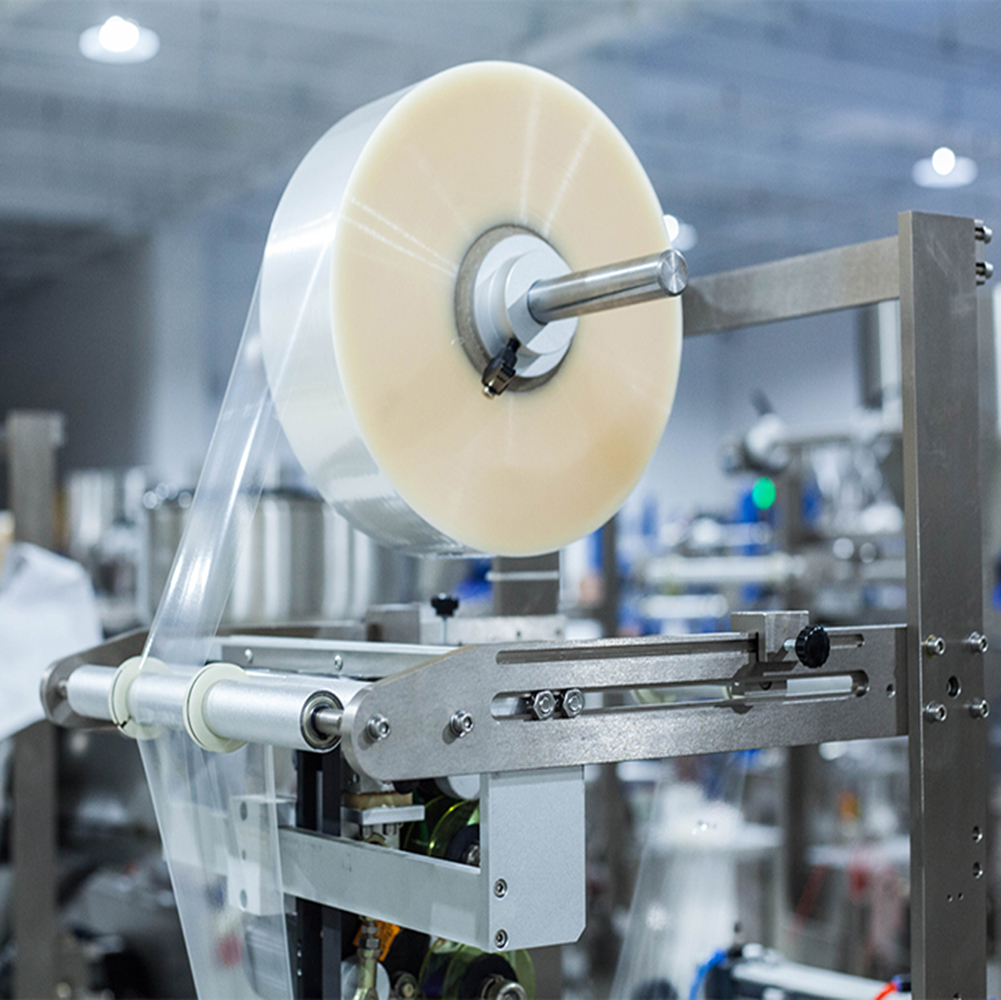

The cellophane packaging machine from DBAO Packaging Machinery is a high-performance solution designed to deliver fast, accurate, and hygienic packaging for a wide range of products. This automatic cellophane packaging machine provides precise wrapping, consistent sealing, and visually appealing presentation for candies, chocolates, biscuits, and other food items. Constructed from durable food-grade stainless steel and equipped with advanced servo-controlled systems, it meets stringent hygiene standards while ensuring long-term reliability and efficiency. Its versatile design supports multiple packaging formats, including pillow packs, flow wraps, and individually wrapped items, making it suitable for small confectionery producers as well as large-scale industrial operations. With an intuitive touchscreen interface, rapid changeover capability, and low-maintenance design, this machine helps manufacturers increase productivity, reduce labor costs, and deliver premium-quality packaged products with every batch.

Key Features

- High-Speed Operation – Capable of efficiently handling large-scale packaging tasks.

- Precise Wrapping & Sealing – Guarantees consistent, leak-proof, and visually appealing packages.

- Multi-Product Compatibility – Ideal for candies, chocolates, biscuits, and confectionery items.

- User-Friendly Touchscreen Controls – Simplifies setup, operation, and monitoring.

- Food-Grade Stainless Steel Construction – Ensures hygiene, durability, and compliance with food safety standards.

- Flexible Packaging Formats – Supports pillow packs, flow wraps, and individual wrappers.

- Low Maintenance & Easy Cleaning – Reduces downtime and operating costs.

- Energy-Efficient Design – Optimized to maintain high performance while minimizing power consumption.

Applications

- Confectionery & Chocolates – Wrapping candies, chocolate bars, and pralines.

- Biscuits & Bakery Items – Individual or multi-pack cellophane packaging.

- Snack Foods & Nuts – Ensures fresh, secure, and attractive packaging.

- Promotional or Sample Packs – Small batches for giveaways or trial sales.

- Pharmaceutical & Cosmetic Items – Packaging small products requiring hygienic wrapping.