Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | 35–70 Bags/Min | 35–70 Bags/Min |

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Machine Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

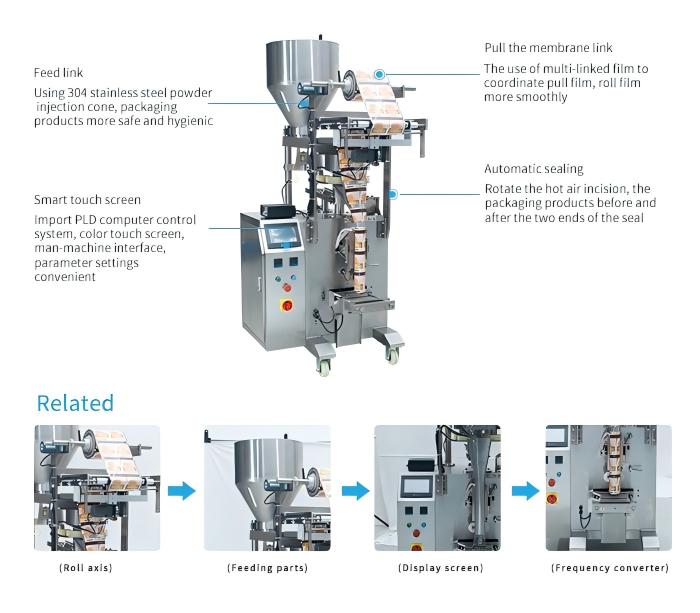

The DBAO Corn Packing Machine is engineered to meet the demanding needs of modern food and agricultural processing. With optimized conveying, dosing, and sealing technology, the corn packaging solution reduces manual labor, prevents material loss, and ensures hygienic packaging that meets global food safety standards. From small farm product processors to large commercial grain packaging plants, our machine supports a wide range of production environments, improving workflow while reducing costs.

Key Features

- High-precision weighing system to ensure accurate corn filling and reduce product giveaway.

- Multiple bag formats supported, including pillow bags, gusset bags, quad seal bags, and zipper pouches.

- Food-grade contact parts designed to maintain hygiene and prevent contamination.

- Flexible feeding options compatible with Z-type elevators, conveyors, and combination weighers.

- Stable and continuous operation suitable for medium to large-scale packaging lines.

- User-friendly HMI touch screen for easy control, recipe setting, and troubleshooting.

- Compatible with nitrogen flushing to enhance freshness and protect taste.

- Low maintenance structure with durable, corrosion-resistant components.