Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | 35–70 Bags/Min | 35–70 Bags/Min |

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Machine Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

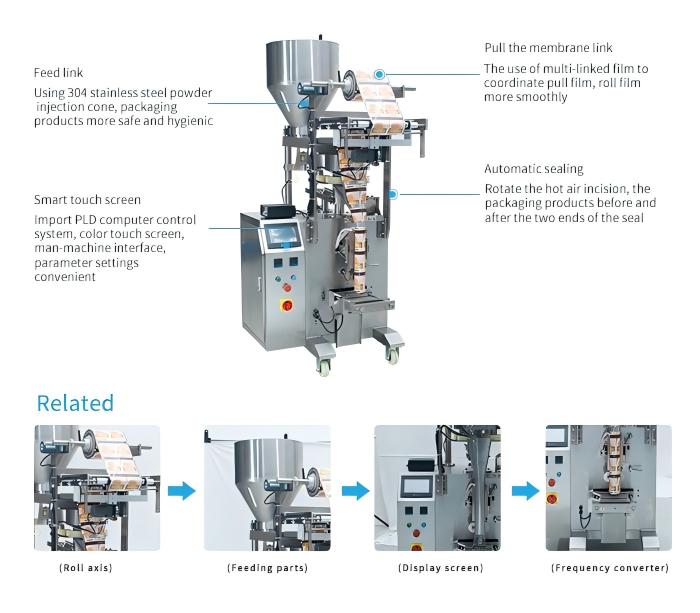

The DBAO Desiccant Packaging Machine is designed to deliver consistent, high-accuracy dosing and secure sealing for a wide range of moisture-absorbing materials. As industries increasingly rely on desiccants to protect products from humidity damage, the need for precise and contamination-free packaging becomes even more essential. Our machine is specially engineered for the small-dose, high-speed nature of desiccant filling, ensuring that every sachet meets exact weight requirements while maintaining material flow stability and packaging integrity.

Why Choose DBAO Packaging Machinery

- 14+ years of expertise in automated packaging technology serving 70+ global markets.

- Premium electrical components from reputable brands such as Panasonic, ensuring stable and long-lasting performance.

- Tailor-made OEM/ODM solutions for different sachet formats, gram weight ranges, and production capacities.

- Comprehensive after-sales support with remote diagnostics, spare parts supply, and technical training.

- Strong production capacity with two specialized workshops and over 1,500 successful machine installations worldwide.