Mechanical Parameter

| Similar Mainframe Model Specifications (Product Size Selection Models) | |||||

| Type | DB-420 | DB-520 | DB-720 | DB-900 | DB-1200 |

Film Width | Max. 420 mm | Max. 520 mm | Max. 720 mm | Max. 900 mm | Max. 1200 mm |

Bag Length | 80-300 mm | 80-350 mm | 180-350 mm | 100-600 mm | 100-1000 mm |

Bag Width | 60-200 mm | 100-250 mm | 100-500 mm | 260-430 mm | 290-580 mm |

Film Roll Diameter | Max. 320 mm | Max. 320 mm | Max. 320 mm | Max. 400 mm | Max. 400 mm |

Packaging Rate | 5-60 Bags/Min | 5-60 Bags/Min | 5-55 Bags/Min | 5-20 Bags/Min | 5-20 Bags/Min |

Power | 220V 50/60 Hz, 2 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 4.5 kW | 220V 50/60 Hz, 5 kW |

Measurement Range | 150-1500 ml | 2000 ml | 4000 ml | 1-25 ml | 1.5-45 ml |

Film Thickness | 0.04-0.08 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm |

Machine Size (LxWxH) | 1217x1015x1343 mm | 1488x1080x1490 mm | 1780x1350x2050 mm | 2305x1686x2725 mm | 2900x2050x3500 mm |

Weight | About 650 KG | About 680 KG | About 750 KG | ||

Certification | CE/SGS/ISO Certification | ||||

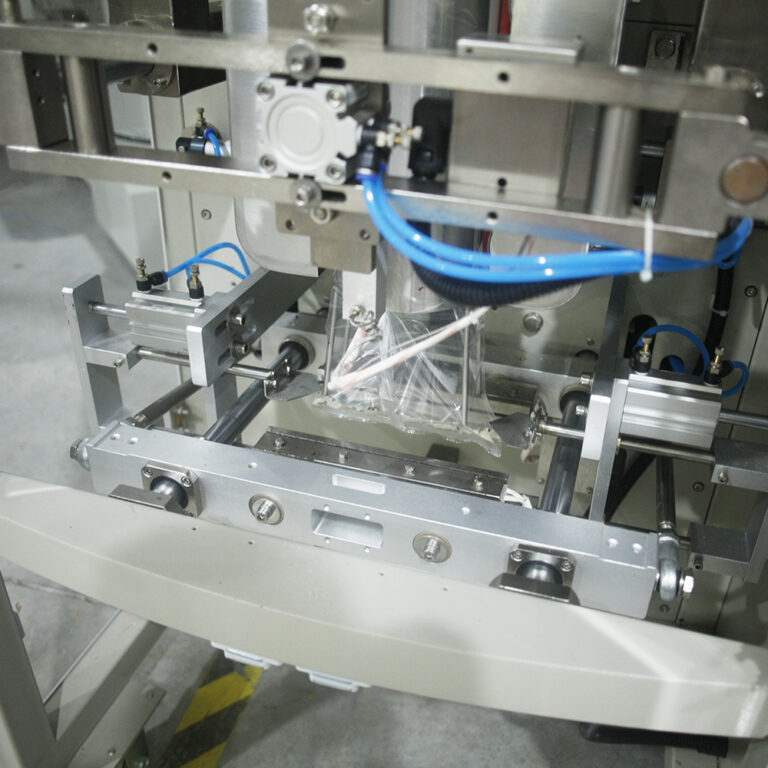

The FFS machine (Form Fill Seal machine) is an advanced packaging solution designed to optimize speed, precision, and flexibility in modern production lines. What makes DBAO’s FFS machines stand out is their ability to seamlessly integrate bag forming, product filling, and secure sealing into a single, continuous process. This automation not only reduces manual labor but also minimizes errors and ensures uniform packaging quality at high output speeds.

Built with intelligent control systems, high-performance servo technology, and premium-grade components, these machines are engineered for long-term reliability and efficiency. They can easily handle a wide variety of packaging formats—whether pillow bags, gusseted bags, or quad-sealed bags—making them suitable for diverse industries.

Key Features

- High-Speed Performance – Delivers fast and continuous packaging cycles to meet large-scale production needs.

- Accurate Filling – Advanced servo and PLC control systems ensure precise product dosing.

- Flexible Packaging Styles – Supports pillow bags, gusset bags, quad-sealed bags, and more.

- Durable Construction – Built with top-grade materials and components for long-lasting stability.

- User-Friendly Operation – Easy setup, smooth changeovers, and intuitive touch-screen controls.

- Low Maintenance – Designed for efficiency with minimal downtime and reduced operating costs.

Why Choose DBAO Packaging Machinery?

- Experience – More than 14 years specializing in packaging machine research, design, and manufacturing.

- Technology – Incorporates intelligent third-generation design with stable and precise performance.

- Customization – Tailored solutions to match your product type and packaging requirements.

- Quality – Uses trusted international brands for electrical and mechanical parts to ensure durability.

- Global Reach – Over 1,500 machines in use across 70+ countries worldwide.

- Complete Solutions – Offers auxiliary equipment like check weighers, metal detectors, labeling systems, and nitrogen generators.

- Service – Provides 24/7 customer support, rapid spare parts supply, and hands-on training.

- Innovation – Constant R&D investment ensures machines remain efficient, eco-friendly, and future-ready.