Mechanical Parameter

| Similar Mainframe Model Specifications (Product Size Selection Models) | |||||

| Type | DB-420 | DB-520 | DB-720 | DB-900 | DB-1200 |

Film Width | Max. 420 mm | Max. 520 mm | Max. 720 mm | Max. 900 mm | Max. 1200 mm |

Bag Length | 80-300 mm | 80-350 mm | 180-350 mm | 100-600 mm | 100-1000 mm |

Bag Width | 60-200 mm | 100-250 mm | 100-500 mm | 260-430 mm | 290-580 mm |

Film Roll Diameter | Max. 320 mm | Max. 320 mm | Max. 320 mm | Max. 400 mm | Max. 400 mm |

Packaging Rate | 5-60 Bags/Min | 5-60 Bags/Min | 5-55 Bags/Min | 5-20 Bags/Min | 5-20 Bags/Min |

Power | 220V 50/60 Hz, 2 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 4.5 kW | 220V 50/60 Hz, 5 kW |

Measurement Range | 150-1500 ml | 2000 ml | 4000 ml | 1-25 ml | 1.5-45 ml |

Film Thickness | 0.04-0.08 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm |

Machine Size (LxWxH) | 1217×1015×1343 mm | 1488×1080×1490 mm | 1780×1350×2050 mm | 2305×1686×2725 mm | 2900×2050×3500 mm |

Weight | About 650 KG | About 680 KG | About 750 KG | ||

Certification | CE/SGS/ISO Certification | ||||

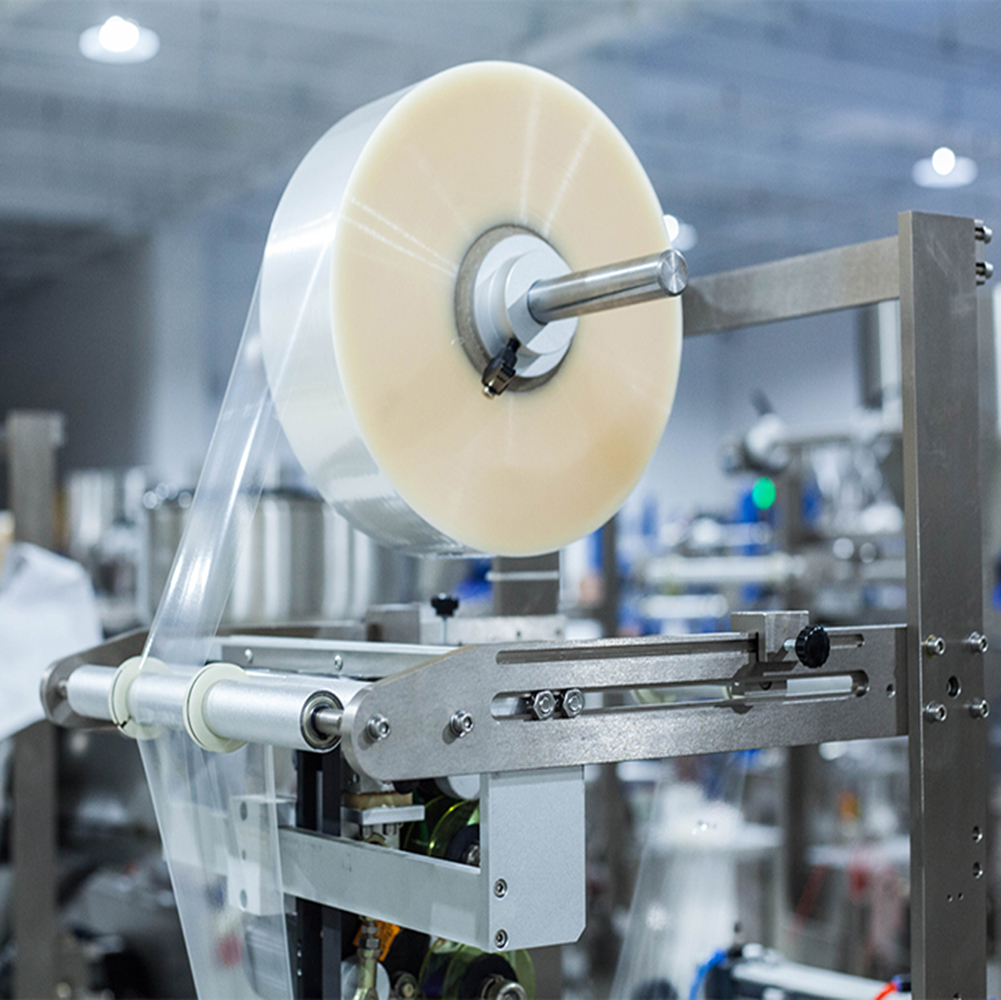

A food pouch filling machine is an essential solution for food manufacturers looking to streamline their packaging process while maintaining product quality, hygiene, and consistency. DBAO’s machines are designed to handle a wide variety of food products—from powders and granules to liquids, sauces, and snacks—delivering precise filling and reliable sealing in every pouch. By integrating forming, filling, and sealing into a single automated process, these machines dramatically improve production efficiency, reduce labor requirements, and minimize product waste.

DBAO’s food pouch filling machines are particularly valued for their versatility and durability. They accommodate different pouch types, including stand-up pouches, zipper pouches, spout pouches, and flat pouches, and support a wide range of sizes and formats. Advanced servo-controlled mechanisms and PLC automation ensure accurate dosing and consistent sealing at high speeds, while hygienic construction and easy-clean designs maintain food safety standards.

Key Features

- High Precision – Accurate filling for powders, granules, liquids, and snacks.

- Fully Automated – Combines forming, filling, and sealing in one seamless process.

- Versatile Pouch Compatibility – Supports stand-up, zipper, spout, and flat pouches.

- Fast Production Speed – Maintains efficiency without compromising quality.

- Durable Build – Premium international components ensure long-term reliability.

- Hygienic Design – Food-grade materials and easy-to-clean structure.

- User-Friendly Operation – Intuitive touchscreen interface and quick setup.

- Reliable Sealing – Airtight and leak-proof pouches for freshness and safety.

Applications

DBAO food pouch filling machines are widely used in:

- Snack Foods – Nuts, chips, puffed snacks, candies, and dried fruits.

- Powdered Foods – Coffee, tea, protein powders, spices, and powdered beverages.

- Liquids & Sauces – Soups, sauces, oils, and condiments.

- Frozen Foods & Ready Meals – Vegetables, fruits, and pre-cooked items.

- Other Food Products – Cereals, grains, and granular ingredients.