Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | ||

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Machine Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

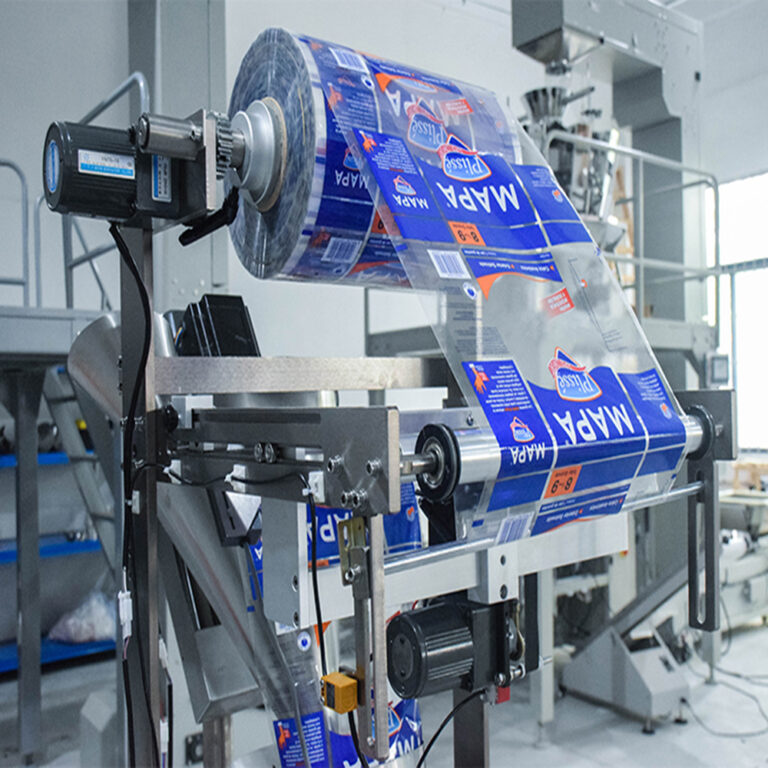

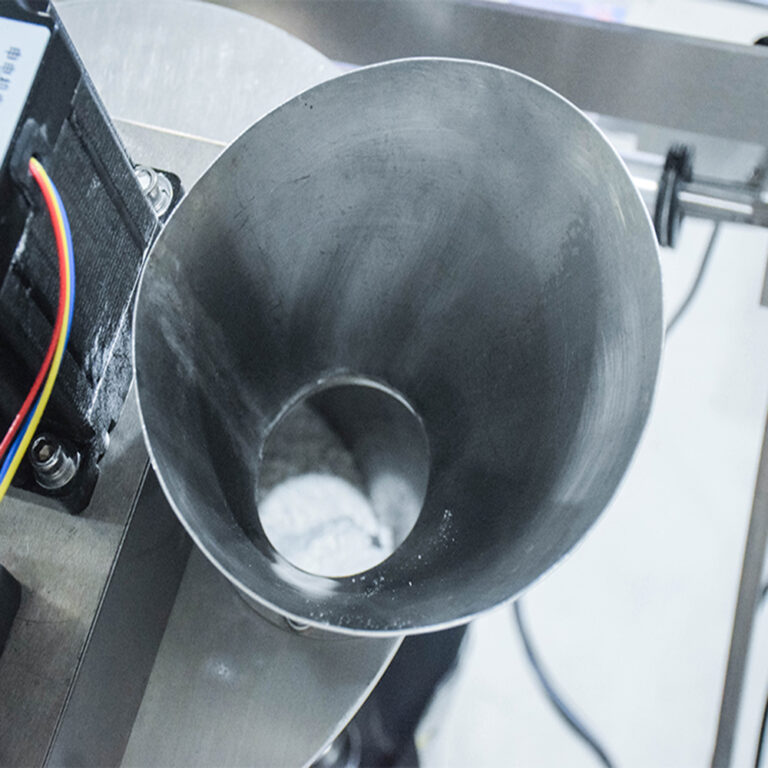

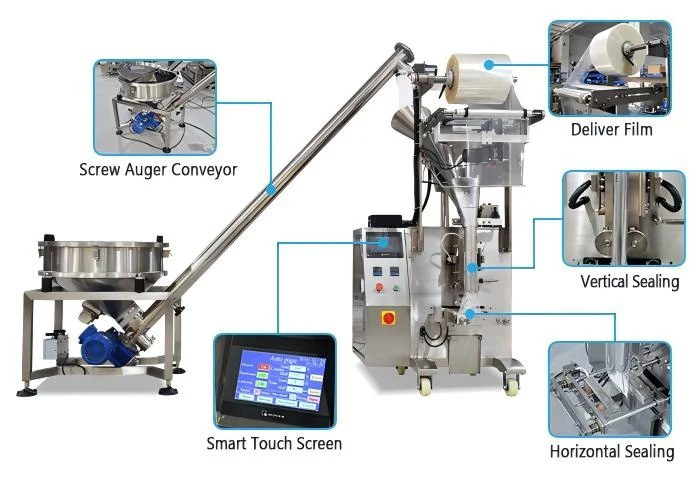

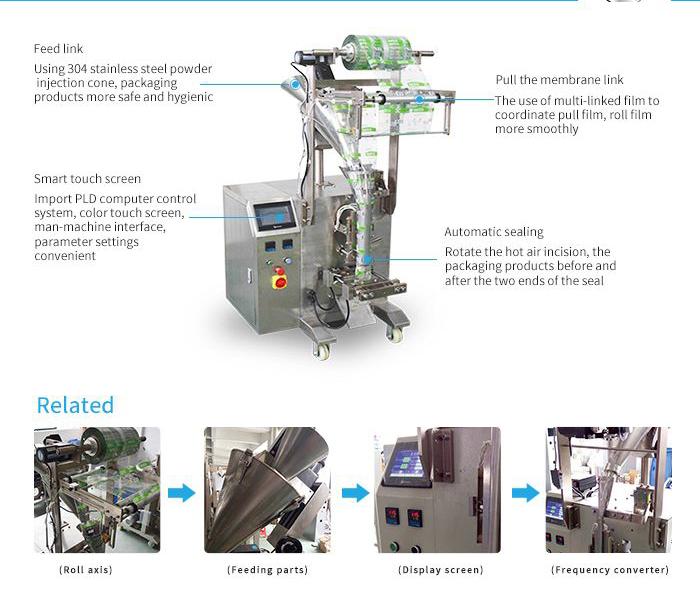

Form fill seal machinery represents a fully integrated packaging solution designed to maximize efficiency, precision, and operational flexibility. Unlike traditional packaging processes, which separate bag forming, product filling, and sealing, DBAO’s form fill seal machinery combines all three steps into a single automated operation. This not only accelerates production but also minimizes material waste and reduces labor requirements, helping manufacturers achieve cost-effective, high-quality packaging on a consistent basis.

DBAO’s form fill seal machinery is engineered to accommodate a wide range of products—from powders, granules, and snacks to liquids, sauces, and semi-solid items—ensuring precise portioning and airtight sealing every time. Equipped with advanced servo-driven mechanisms and intelligent PLC controls, the machinery guarantees stable operation and accurate packaging even under high-speed conditions. Its modular design allows for easy format changes, enabling manufacturers to switch between pillow bags, gusseted bags, quad-seal pouches, and stand-up bags with minimal downtime.

Applications

DBAO form fill seal machinery is suitable for:

- Food & Beverage – Rice, sugar, grains, snacks, sauces, frozen foods, and condiments.

- Pharmaceuticals & Healthcare – Powders, capsules, tablets, and herbal products.

- Chemicals & Industrial Products – Fertilizers, detergents, and granular materials.

- Pet Food – Dry kibble, treats, and nutritional supplements.

- Daily Consumables – Seeds, powders, and household goods.

Why Choose DBAO Packaging Machinery?

- Experience & Expertise – Over 14 years of dedicated experience in designing and manufacturing advanced packaging machinery.

- Cutting-Edge Technology – Intelligent, third-generation automated systems for reliable and high-speed performance.

- Tailored Solutions – Customizable machines to fit your product types, bag formats, and production goals.

- Premium Components – Built with internationally recognized parts to ensure durability and stability.

- Global Trust – Over 1,500 machines running in more than 70 countries worldwide.

- Complete Packaging Line – Supporting equipment including check weighers, labeling systems, and nitrogen generators.

- Professional Support – 24/7 technical assistance, spare parts supply, and training for operators.

- Innovative Approach – Continuous R&D ensures efficiency, sustainability, and adaptability.