Mechanical Parameter

| Similar Mainframe Model Specifications (Product Size Selection Models) | |||||

| Type | DB-420 | DB-520 | DB-720 | DB-900 | DB-1200 |

Film Width | Max. 420 mm | Max. 520 mm | Max. 720 mm | Max. 900 mm | Max. 1200 mm |

Bag Length | 80-300 mm | 80-350 mm | 180-350 mm | 100-600 mm | 100-1000 mm |

Bag Width | 60-200 mm | 100-250 mm | 100-500 mm | 260-430 mm | 290-580 mm |

Film Roll Diameter | Max. 320 mm | Max. 320 mm | Max. 320 mm | Max. 400 mm | Max. 400 mm |

Packaging Rate | 5–60 Bags/Min | 5–60 Bags/Min | 5–55 Bags/Min | 5–20 Bags/Min | 5–20 Bags/Min |

Power | 220V 50/60 Hz, 2 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 4.5 kW | 220V 50/60 Hz, 5 kW |

Measurement Range | 150–1500 ml | 2000 ml | 4000 ml | 1-25 ml | 1.5-45 ml |

Film Thickness | 0.04-0.08 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm |

Machine Size (LxWxH) | 1217x1015x1343 mm | 1488x1080x1490 mm | 1780x1350x2050 mm | 2305x1686x2725 mm | 2900x2050x3500 mm |

Weight | About 650 KG | About 680 KG | About 750 KG | ||

Certification | CE/SGS/ISO Certification | ||||

When efficiency and consistency are critical to your packaging line, investing in a form fill sealing machine can transform your production process. DBAO’s advanced systems are engineered to automate the entire workflow—from forming the packaging material into shape, filling it with product, and applying a secure seal—all in one seamless cycle. This integrated design not only accelerates production speed but also ensures a higher degree of accuracy and repeatability compared to traditional methods.

Built for versatility, DBAO form fill sealing machines handle a wide range of products, including powders, liquids, granules, and pastes, making them suitable for businesses with diverse packaging needs. Their compact footprint allows easy installation even in facilities with limited space, while the stainless-steel build guarantees hygiene and resilience for industries with strict safety standards.

Key Features

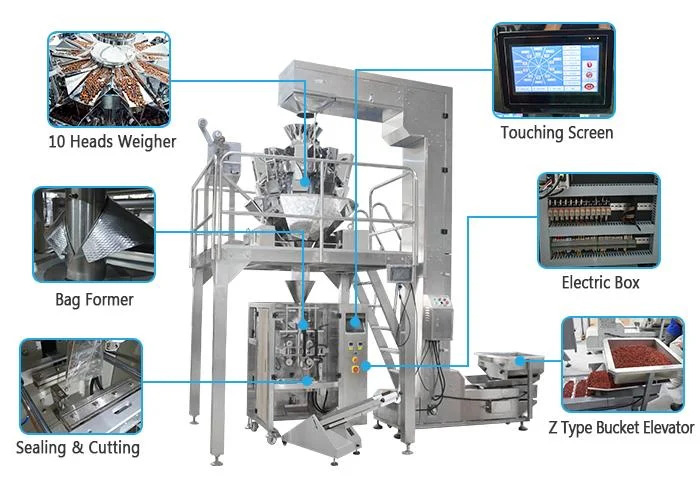

- Integrated Process – Combines forming, filling, and sealing in one continuous cycle.

- Versatile Packaging – Suitable for powders, liquids, pastes, and granules.

- High-Speed Output – Delivers consistent performance for large-scale production.

- Precision Dosing – Ensures accurate and uniform product filling.

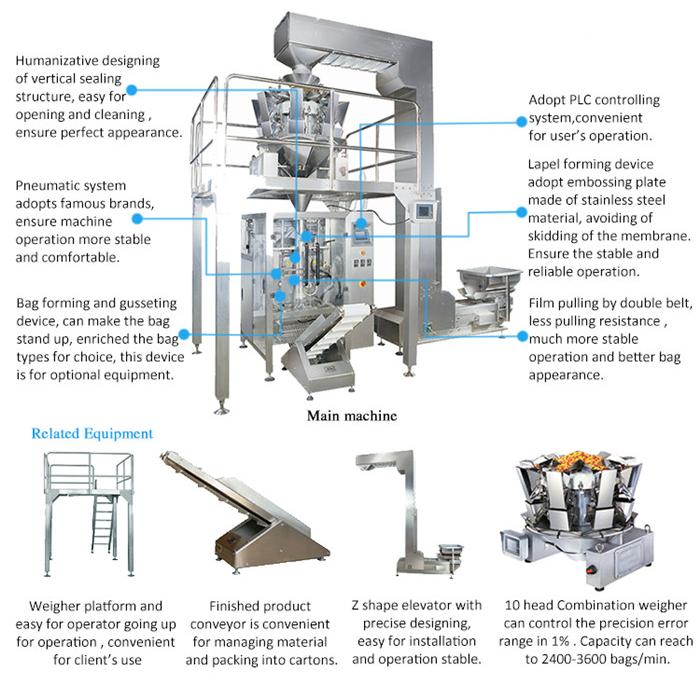

- User-Friendly Interface – Easy-to-operate PLC and touch-screen control system.

- Durable & Hygienic – Stainless-steel construction for long service life and food safety.

- Quick Changeovers – Fast adjustments for different bag sizes and product types.

- Energy-Saving Design – Optimized for reduced power consumption.

Applications

DBAO form fill sealing machines are widely used in:

- Food & Beverage – Coffee, tea, sugar, sauces, snacks, frozen goods, and condiments.

- Pharmaceutical & Healthcare – Powders, syrups, oral liquids, capsules, and medical sachets.

- Cosmetics & Personal Care – Creams, lotions, gels, shampoos, and trial packs.

- Chemical & Industrial – Fertilizers, detergents, adhesives, and industrial powders.