Mechanical Parameter

| Similar Mainframe Model Specifications (Product Size Selection Models) | |||||

| Type | DB-420 | DB-520 | DB-720 | DB-900 | DB-1200 |

Film Width | Max. 420 mm | Max. 520 mm | Max. 720 mm | Max. 900 mm | Max. 1200 mm |

Bag Length | 80-300 mm | 80-350 mm | 180-350 mm | 100-600 mm | 100-1000 mm |

Bag Width | 60-200 mm | 100-250 mm | 100-500 mm | 260-430 mm | 290-580 mm |

Film Roll Diameter | Max. 320 mm | Max. 320 mm | Max. 320 mm | Max. 400 mm | Max. 400 mm |

Packaging Rate | 5–60 Bags/Min | 5–60 Bags/Min | 5–55 Bags/Min | 5–20 Bags/Min | 5–20 Bags/Min |

Power | 220V 50/60 Hz, 2 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 4.5 kW | 220V 50/60 Hz, 5 kW |

Measurement Range | 150–1500 ml | 2000 ml | 4000 ml | 1-25 ml | 1.5-45 ml |

Film Thickness | 0.04-0.08 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm |

Machine Size (LxWxH) | 1217x1015x1343 mm | 1488x1080x1490 mm | 1780x1350x2050 mm | 2305x1686x2725 mm | 2900x2050x3500 mm |

Weight | About 650 KG | About 680 KG | About 750 KG | ||

Certification | CE/SGS/ISO Certification | ||||

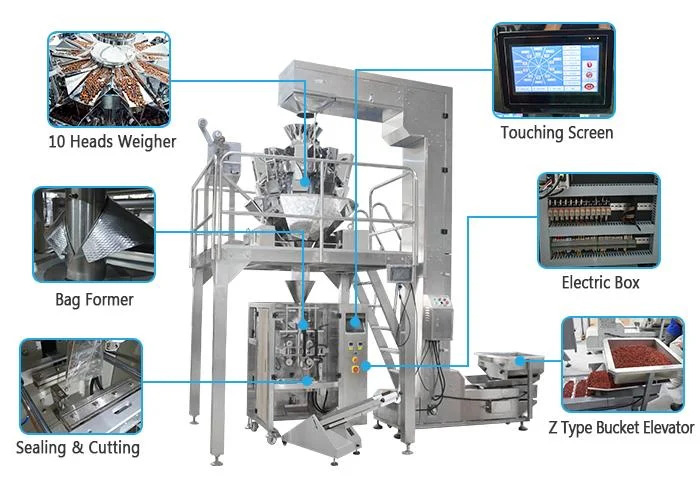

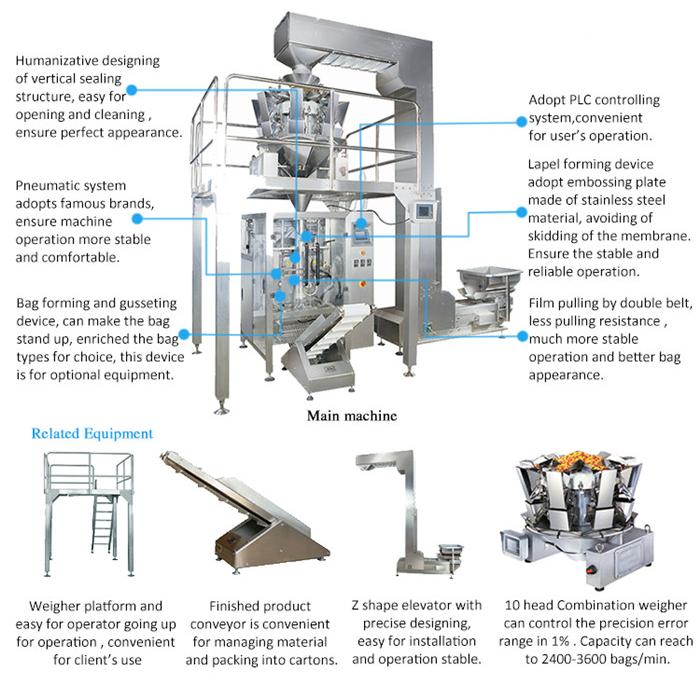

Pouch filling machines are designed to revolutionize the packaging process by offering a fully automated solution that combines accuracy, efficiency, and flexibility. DBAO’s pouch filling machines are engineered to handle a wide variety of products, including powders, granules, liquids, pastes, and semi-solids, while maintaining precise fill weights and consistent pouch sealing. By integrating advanced servo-driven mechanisms, PLC controls, and premium sealing technology, these machines streamline the workflow, reduce labor requirements, and minimize product waste.

One of the key strengths of DBAO’s pouch filling machines is their adaptability. They support multiple pouch types such as stand-up pouches, zipper pouches, spout pouches, and flat pouches, enabling manufacturers to switch between product lines quickly and efficiently. The machines are designed for easy operation, rapid changeovers, and hygienic processing, ensuring products remain safe and fresh.

Key Features

- High Precision – Accurate filling for powders, granules, liquids, and pastes.

- Fully Automated – Combines filling and sealing in a single streamlined process.

- Versatile Pouch Compatibility – Supports stand-up, zipper, spout, and flat pouches.

- Fast Production Speeds – Maintains efficiency without compromising accuracy.

- Durable Construction – Premium materials and international components ensure reliability.

- Hygienic Design – Easy-to-clean and compliant with industry food safety standards.

- User-Friendly Operation – Intuitive touchscreen interface with quick setup and monitoring.

- Consistent Sealing – Airtight, leak-proof seals to protect product integrity and freshness.

Applications

DBAO pouch filling machines are widely applied across industries, including:

- Food & Beverage – Snacks, nuts, grains, candy, sauces, frozen foods, and liquids.

- Pharmaceuticals & Healthcare – Powders, tablets, supplements, and herbal products.

- Pet Food – Dry kibble, treats, and nutritional products.

- Chemicals & Industrial Products – Fertilizers, detergents, and granular materials.

- Daily Necessities – Seeds, powders, and other household products.