Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | 35–70 Bags/Min | 35–70 Bags/Min |

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Machine Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

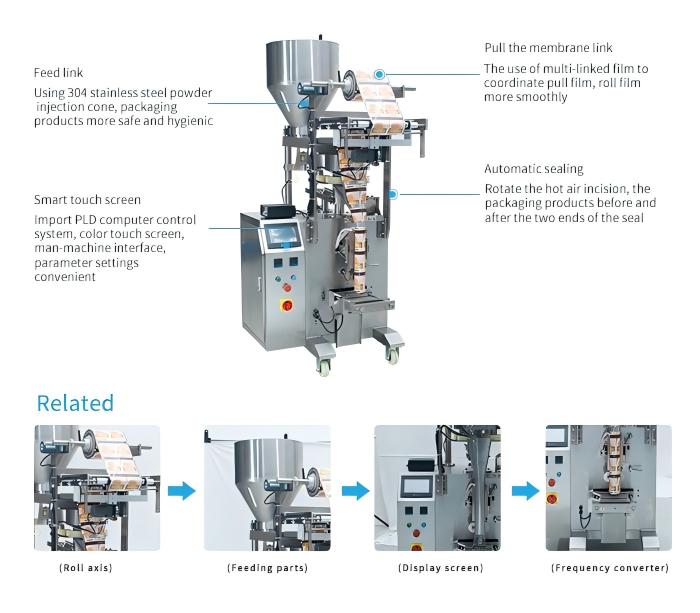

In today’s competitive market, manufacturers demand packaging solutions that combine efficiency, reliability, and flexibility—and that’s exactly what DBAO’s pouch packing machines deliver. Designed to streamline operations, these machines integrate advanced automation with robust engineering to ensure every pouch is filled, sealed, and secured with absolute consistency.

One of the key advantages of DBAO’s pouch packing equipment lies in its adaptability. From powders and liquids to granules and ready-to-eat snacks, the system is engineered to handle a broad spectrum of product types and packaging formats. Businesses benefit from reduced downtime thanks to quick-change features, intuitive controls, and user-friendly operation, allowing operators to switch easily between different pouch styles and product categories.

Key Features

- High-Speed Performance – Maximizes productivity without compromising accuracy.

- Multi-Product Compatibility – Supports powders, liquids, solids, and granules.

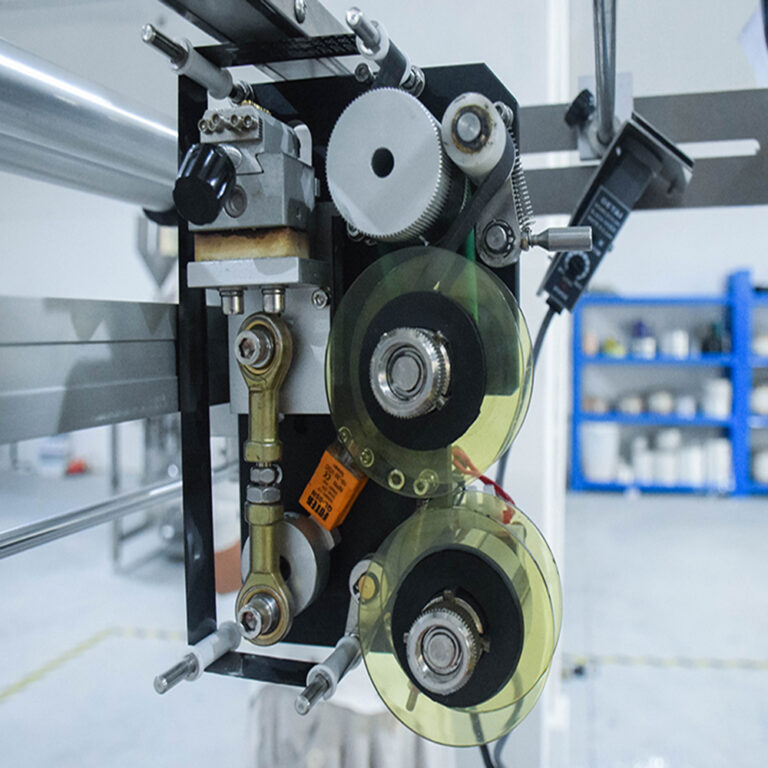

- Advanced Sealing Technology – Ensures strong, reliable seals for product protection.

- Flexible Packaging Formats – Accommodates stand-up pouches, flat pouches, and gusset bags.

- Hygienic Design – Stainless-steel build suitable for food and pharma industries.

- User-Friendly Operation – Touchscreen controls and easy adjustment options.

- Energy Efficient – Optimized for reduced power consumption and lower running costs.

- Low Maintenance – Simple cleaning and durable structure minimize downtime.

Why Choose DBAO Packaging Machinery?

- Proven Industry Expertise – Years of experience delivering high-performance packaging solutions.

- Custom Engineering – Machines tailored to your product and packaging needs.

- Unmatched Reliability – Built to withstand continuous industrial use.

- Global Presence – Trusted by manufacturers across multiple sectors worldwide.

- Comprehensive Support – From installation to after-sales service and spare parts.

- Cost-Effective Operation – Energy savings and reduced product waste.

- Innovation-Oriented – Constant upgrades to meet evolving packaging standards.

- Long-Term Value – A durable investment designed for sustainable growth.