Mechanical Parameter

| Similar Mainframe Model Specifications (Product Size Selection Models) | |||||

| Type | DB-420 | DB-520 | DB-720 | DB-900 | DB-1200 |

Film Width | Max. 420 mm | Max. 520 mm | Max. 720 mm | Max. 900 mm | Max. 1200 mm |

Bag Length | 80-300 mm | 80-350 mm | 180-350 mm | 100-600 mm | 100-1000 mm |

Bag Width | 60-200 mm | 100-250 mm | 100-500 mm | 260-430 mm | 290-580 mm |

Film Roll Diameter | Max. 320 mm | Max. 320 mm | Max. 320 mm | Max. 400 mm | Max. 400 mm |

Packaging Rate | 5–60 Bags/Min | 5–60 Bags/Min | 5–55 Bags/Min | 5–20 Bags/Min | 5–20 Bags/Min |

Power | 220V 50/60 Hz, 2 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 4.5 kW | 220V 50/60 Hz, 5 kW |

Measurement Range | 150–1500 ml | 2000 ml | 4000 ml | 1-25 ml | 1.5-45 ml |

Film Thickness | 0.04-0.08 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm |

Machine Size (LxWxH) | 1217x1015x1343 mm | 1488x1080x1490 mm | 1780x1350x2050 mm | 2305x1686x2725 mm | 2900x2050x3500 mm |

Weight | About 650 KG | About 680 KG | About 750 KG | ||

Certification | CE/SGS/ISO Certification | ||||

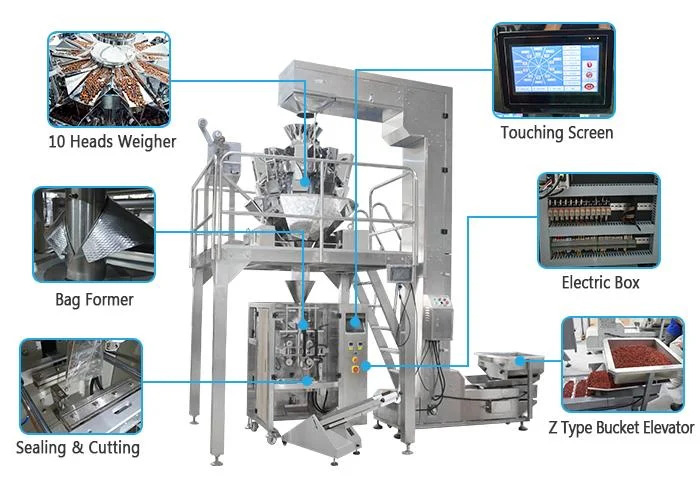

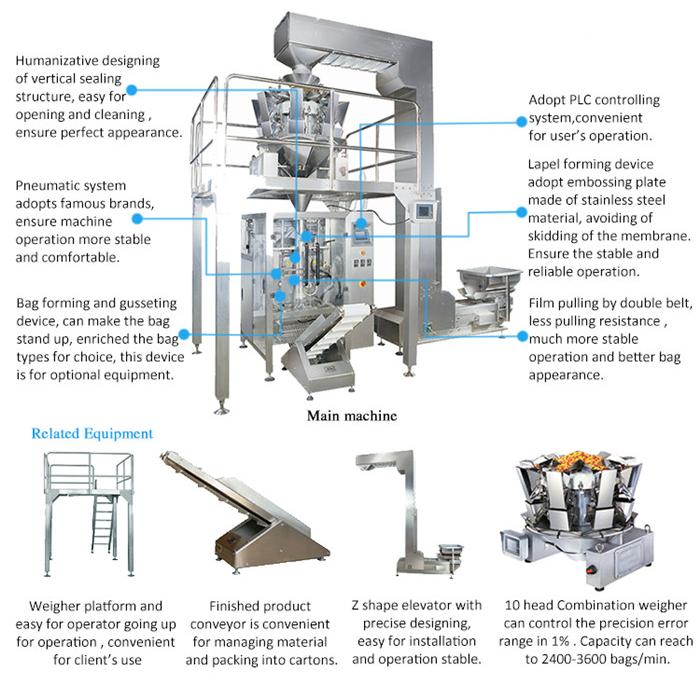

A pouch sealing machine is an essential solution for manufacturers who require secure, airtight packaging that preserves product quality and extends shelf life. At DBAO Packaging Machinery, our pouch sealing machines are designed with advanced automation technology, precision sealing systems, and durable components to ensure consistent performance at high production speeds. Whether handling powders, liquids, granules, or solids, these machines deliver strong, leak-proof seals that meet the strictest packaging standards.

What sets DBAO’s pouch sealing machines apart is their adaptability and reliability. Equipped with intelligent PLC controls, servo-driven operation, and user-friendly touch-screen interfaces, they offer precise control over sealing temperature, pressure, and timing. This guarantees uniform seals across various pouch formats such as stand-up pouches, zipper bags, spout pouches, and four-side sealed bags. Their compact design saves valuable floor space, while hygienic construction and easy-to-clean surfaces make them ideal for food, pharmaceutical, and chemical industries.

Applications

DBAO pouch sealing machines are widely used in:

- Food Industry – Snacks, frozen foods, sauces, condiments, coffee, and pet food.

- Pharmaceuticals & Healthcare – Powders, supplements, tablets, and medical supplies.

- Chemicals & Industrial – Fertilizers, detergents, granular chemicals, and adhesives.

- Cosmetics & Personal Care – Creams, gels, and beauty powders.

- Agriculture – Seeds, feeds, and specialty agricultural products.

Why Choose DBAO Packaging Machinery?

- Proven Expertise – 14+ years of manufacturing experience in advanced sealing and packaging machinery.

- Innovative Technology – Machines equipped with intelligent sealing controls for stable performance.

- Flexible Solutions – Customizable to different pouch types, materials, and production needs.

- Premium Quality Components – Built with trusted international parts for superior durability.

- Comprehensive Range – From pouch sealing to full packaging lines with auxiliary equipment.

- Global Footprint – 1,500+ machines operating successfully across 70+ countries.

- Dedicated Support – 24/7 customer service, spare parts supply, and technical training.

- Long-Term Value – Reliable performance that reduces downtime and maximizes productivity.