Mechanical Parameter

| Similar Mainframe Model Specifications (Product Size Selection Models) | |||||

| Type | DB-420 | DB-520 | DB-720 | DB-900 | DB-1200 |

Film Width | Max. 420 mm | Max. 520 mm | Max. 720 mm | Max. 900 mm | Max. 1200 mm |

Bag Length | 80-300 mm | 80-350 mm | 180-350 mm | 100-600 mm | 100-1000 mm |

Bag Width | 60-200 mm | 100-250 mm | 100-500 mm | 260-430 mm | 290-580 mm |

Film Roll Diameter | Max. 320 mm | Max. 320 mm | Max. 320 mm | Max. 400 mm | Max. 400 mm |

Packaging Rate | 5–60 Bags/Min | 5–60 Bags/Min | 5–55 Bags/Min | 5–20 Bags/Min | 5–20 Bags/Min |

Power | 220V 50/60 Hz, 2 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 3 kW | 220V 50/60 Hz, 4.5 kW | 220V 50/60 Hz, 5 kW |

Measurement Range | 150–1500 ml | 2000 ml | 4000 ml | 1-25 ml | 1.5-45 ml |

Film Thickness | 0.04-0.08 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm |

Machine Size (LxWxH) | 1217x1015x1343 mm | 1488x1080x1490 mm | 1780x1350x2050 mm | 2305x1686x2725 mm | 2900x2050x3500 mm |

Weight | About 650 KG | About 680 KG | About 750 KG | ||

Certification | CE/SGS/ISO Certification | ||||

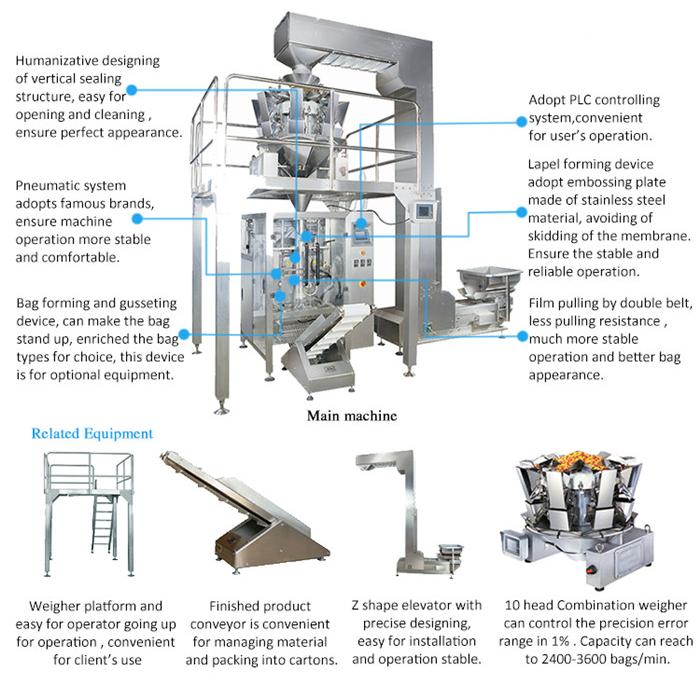

DBAO Packaging Machinery’s sealing machines for packaging are engineered to deliver high efficiency, precision, and durability across diverse industries. Whether you handle food products, frozen goods, liquids, powders, or pharmaceuticals, our machines provide seamless and consistent sealing, enhancing both product safety and shelf life. Leveraging over 14 years of manufacturing expertise, DBAO integrates advanced technology, intelligent controls, and high-quality components to offer solutions that boost production efficiency, reduce material waste, and ensure dependable operation.

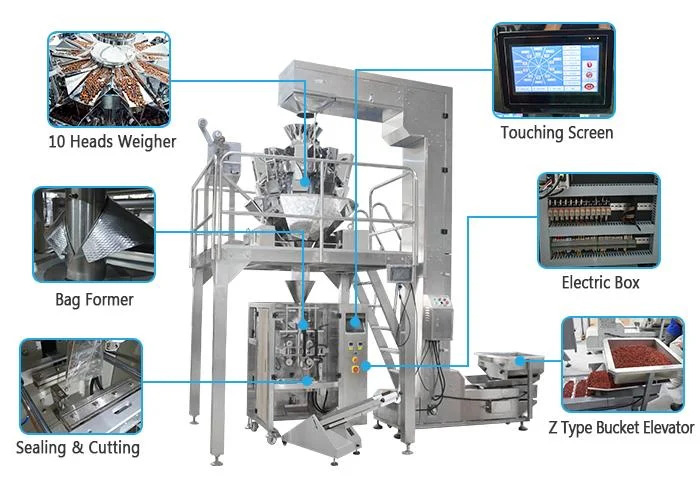

Our automatic packing machines, including Vertical Form Fill Seal (VFFS) machines, Doypack packing machines, and multi-lane packing machines, are optimized for a variety of bag styles, such as pillow bags, gusset bags, stick bags, zipper pouches, and spout pouches. With user-friendly controls and robust construction, these sealing machines are designed for smooth operation, minimal downtime, and long-term reliability.

Key Features

- High Precision Sealing: Ensures airtight packaging, maintaining product quality and freshness.

- Versatile Bag Compatibility: Supports multiple bag types including quad seal, five-seal, center-seal, and more.

- Advanced Automation: Intelligent control systems for accurate filling, cutting, and sealing with minimal human intervention.

- Durable Components: Equipped with premium Panasonic PLCs, servo motors, and international-grade parts.

- Easy Operation & Maintenance: User-friendly interfaces, fast setup, and accessible parts reduce downtime.

- Customizable Configurations: Machines tailored for different production capacities, bag sizes, and material types.

Why Choose DBAO Packaging Machinery

- Proven Expertise: 14+ years of experience in designing and manufacturing packaging machines.

- Global Reliability: Over 1,500 machines in operation across 70+ countries worldwide.

- Comprehensive Solutions: Full-line automation including check weighers, labeling machines, nitrogen flushing, and metal detectors.

- Tailored Services: OEM and ODM options to meet your unique production requirements.

- Exceptional Support: 24/7 professional technical guidance and prompt after-sales service ensure peace of mind.