Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | ||

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

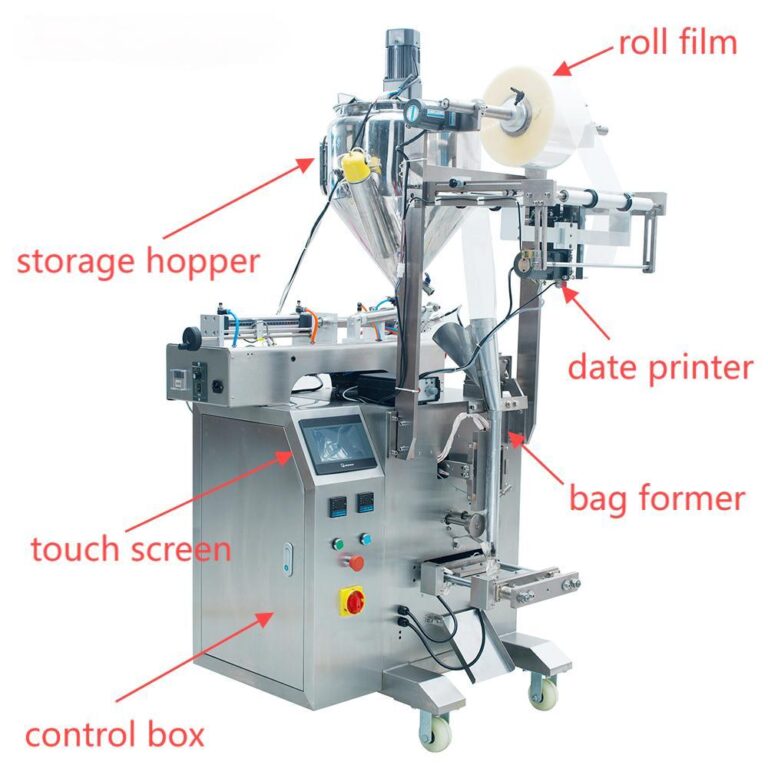

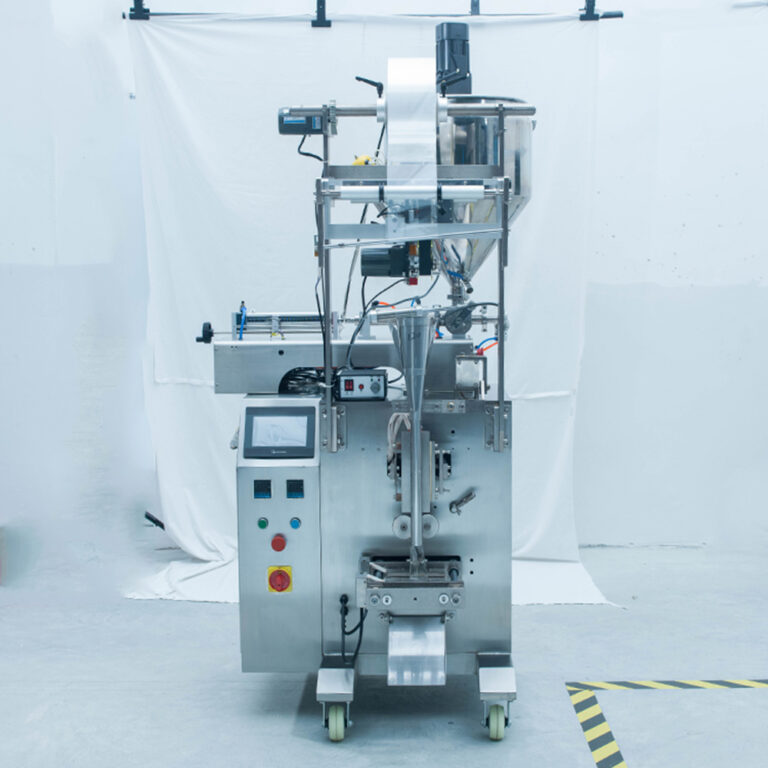

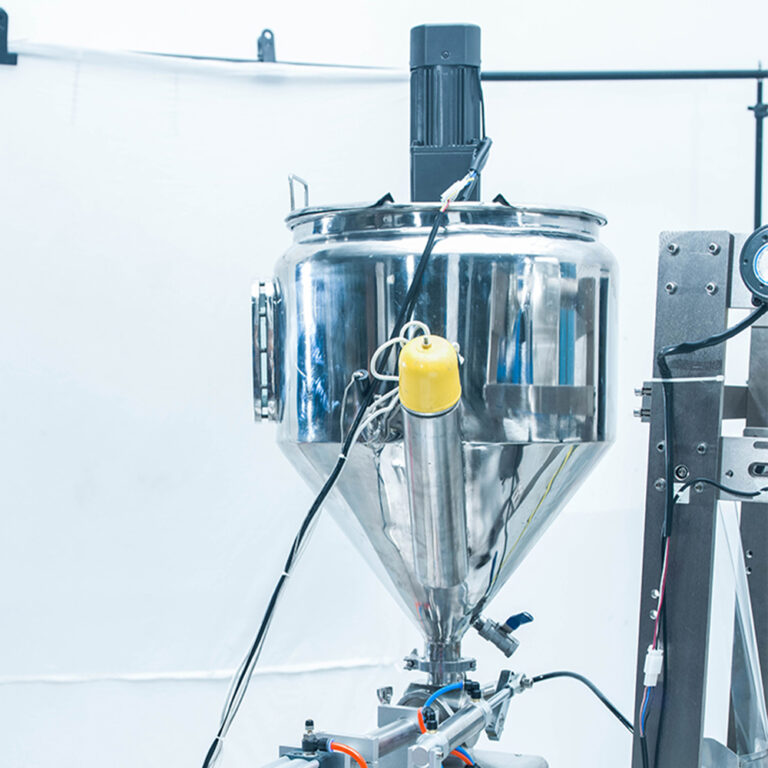

Efficient and reliable snack packing machinery is crucial for today’s competitive food industry, where packaging must not only protect freshness but also enhance shelf appeal. DBAO Packaging Machinery designs and manufactures advanced snack packing machines that combine high-speed automation, precise weighing, and durable sealing technology. These machines integrate forming, filling, and sealing into one streamlined process, minimizing manual labor and boosting production output while maintaining consistent quality.

DBAO’s snack packing machinery is built to handle a wide variety of snack products—ranging from chips, nuts, and candy to puffed foods, biscuits, and granola. With intelligent PLC controls, servo-driven systems, and customizable bagging formats, our machines offer unmatched flexibility for different snack types and packaging styles such as pillow bags, gusset bags, zipper pouches, and quad-seal bags.

Key Features

- High-Speed Automation – Fast and efficient production for snack packaging lines.

- Accurate Weighing & Filling – Consistent portion control for powders, granules, and solids.

- Versatile Packaging Formats – Supports pillow bags, gusset bags, zipper pouches, and quad-seal bags.

- Durable Sealing System – Ensures airtight, leak-proof packaging for product freshness.

- Smart Controls – PLC and touchscreen interface for precise, user-friendly operation.

- Premium Components – Built with trusted international parts for reliability and long lifespan.

- Hygienic Construction – Easy-to-clean surfaces designed to meet food safety standards.

- Compact & Robust Design – Space-saving structure suitable for different production environments.

Applications

DBAO snack packing machinery is widely used for:

- Chips & Crisps – Ensuring freshness and maintaining texture.

- Nuts & Seeds – Preserving natural flavor and extending shelf life.

- Candies & Confectionery – Attractive, portion-controlled packaging.

- Biscuits & Cookies – Reliable sealing to protect delicate items.

- Granola & Cereals – Flexible options for multiple bag types.

- Puffed & Extruded Snacks – Airtight packaging to maintain crispness.