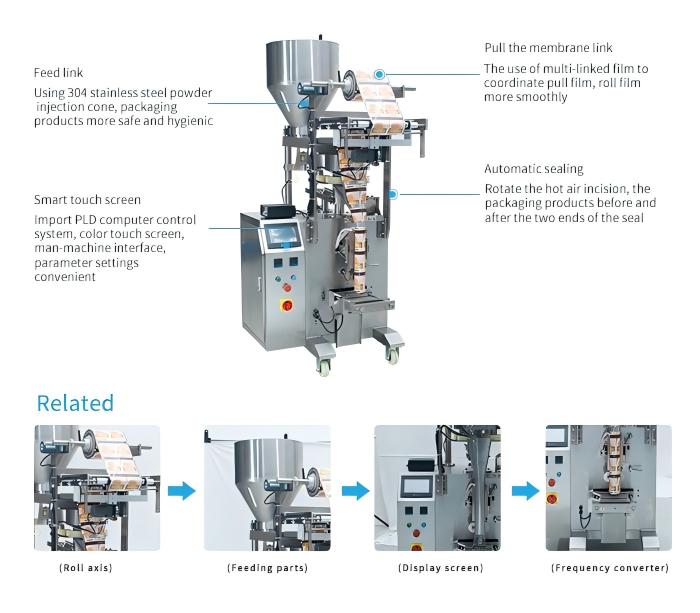

Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | 35–70 Bags/Min | 35–70 Bags/Min |

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Machine Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

The DBAO snacks filling packaging machines are developed to help food businesses achieve superior efficiency, packaging accuracy, and long-term operational stability. Designed with high-speed weighing systems and intelligent automation, these machines ensure that every snack pouch—large or small—is filled consistently, sealed cleanly, and packed with minimal waste. From fragile chips to irregular-shaped nuts and lightweight puffed snacks, the system adapts effortlessly to maintain product integrity throughout the packaging process.

Why Choose DBAO Packaging Machinery

- Specialized expertise in high-speed automated snack packaging systems

- Strong customization capabilities to support different bag sizes, materials, and snack types

- Durable machines engineered for continuous, high-volume production

- Global after-sales service and technical support for stable long-term use

- Reliable quality-control standards, ensuring minimized downtime and maximum productivity