Mechanical Parameter

Type | DB-320 | DB-380 | DB-420 |

Film Width | Max. 320 mm | Max. 380 mm | Max. 420 mm |

Bag Length | 50–200 mm | 60–280 mm | 60–280 mm |

Bag Width | 50–150 mm | 60–180 mm | 60–180 mm |

Film Roll Diameter | Max. 320 mm | ||

Packaging Rate | 35–70 Bags/Min | ||

Power | 220V 50/60 Hz, 2.2 kW | 220V 50/60 Hz, 2.5 kW | 220V 50/60 Hz, 2.5 kW |

Range of Measurement | 50–500 ml | 50–750 ml | 100–1000 ml |

Packing Film Material | OPP/CPP, OPP/PE, BOPP/VEPET/PE, etc. | ||

Size (L×W×H) | 700×580×1550 mm | 970×680×1950 mm | 970×720×1950 mm |

Weight | 250 kg | 300 kg | 400 kg |

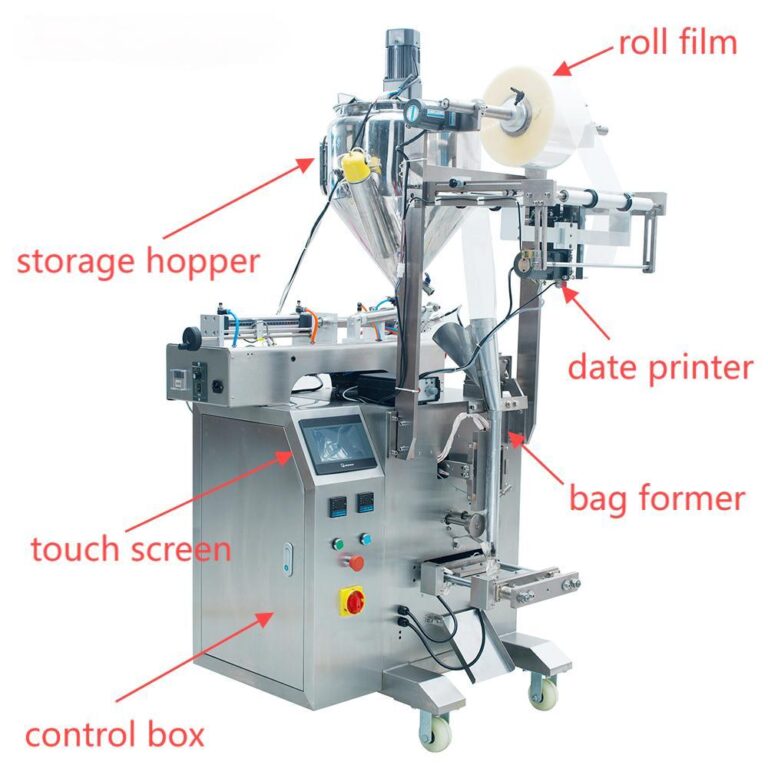

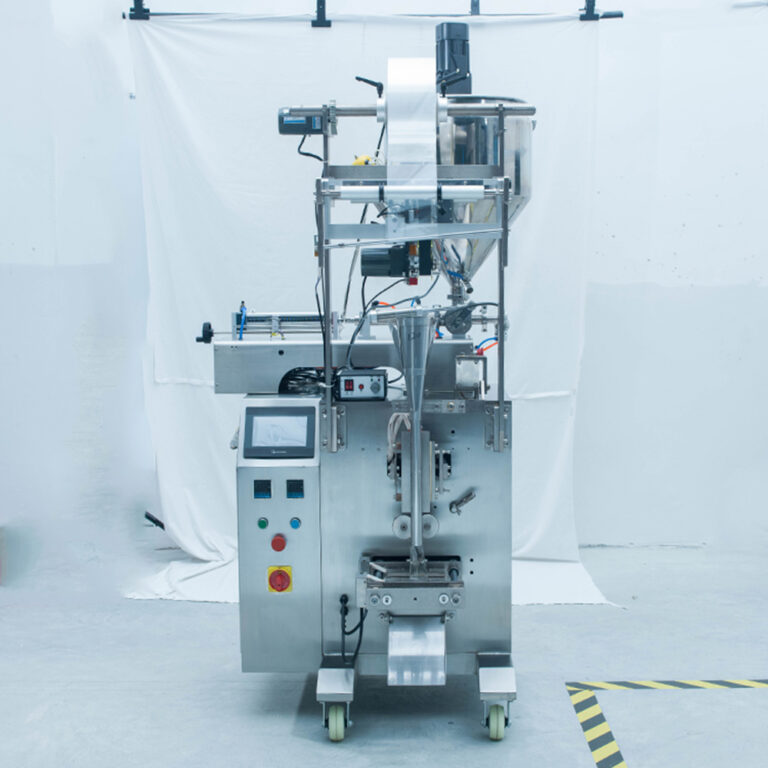

DBAO Packaging Machinery offers state-of-the-art vertical form fill and seal machines that provide efficient, reliable, and customizable packaging solutions for a wide range of products. Our VFFS machines are engineered for high-speed, accurate packaging, ensuring that every product is filled and sealed to the highest standards. Whether you are packaging food, pharmaceuticals, beverages, or chemicals, DBAO’s vertical form fill and seal machines are built to optimize your production line and increase packaging efficiency.

With over 14 years of expertise in the packaging industry, DBAO has established itself as a trusted partner in providing advanced machinery that delivers consistent, high-quality results. Our VFFS machines are fully customizable to meet your unique packaging needs, offering flexible features for various bag sizes, formats, and fill types.

Key Features

- High-Speed Performance: DBAO’s vertical form fill and seal machines are designed to handle high-volume production with fast cycle times. This helps businesses increase output and improve overall efficiency, while maintaining packaging quality.

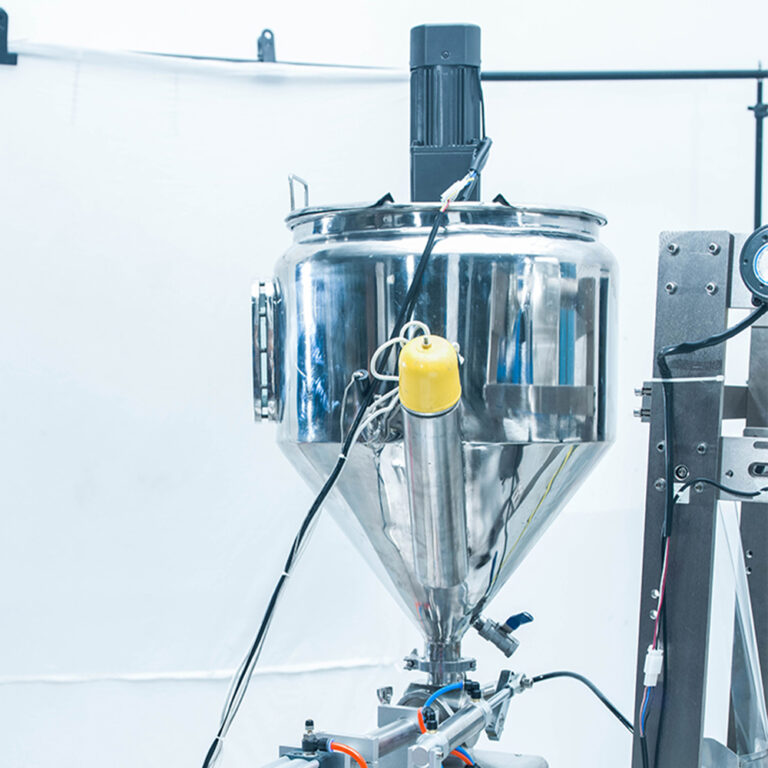

- Precise Filling and Sealing: Our VFFS machines ensure accurate filling of a wide variety of products, from powders and liquids to granules and solids. The machines deliver tight, reliable seals that keep products fresh and secure, extending shelf life and preventing contamination.

- Versatile Bag Formats: DBAO’s vertical form fill and seal machines support various bag styles, including pillow bags, gusseted bags, stand-up pouches, and more. This versatility ensures that your products are packaged in the ideal format, providing optimal functionality and attractive presentation.

- Customizable Features: Whether you need different bag sizes, fill types, or sealing methods, DBAO’s vertical form fill and seal machines are fully customizable. Our machines can be tailored to fit the specific requirements of your production process, enhancing efficiency and flexibility.

Applications

DBAO’s vertical form fill and seal machines are widely used across various industries, providing efficient packaging solutions for a wide range of products. Key applications include:

- Food Packaging: Perfect for packaging snacks, grains, dried fruits, beverages, powdered foods, and more. Our VFFS machines create secure, airtight seals that preserve product freshness and shelf life.

- Pharmaceuticals: Ideal for filling and sealing pharmaceutical products such as tablets, capsules, powders, and liquid medications. DBAO’s vertical form fill and seal machines ensure precise dosing and hygiene compliance while maintaining tamper-resistant packaging.

- Cosmetics and Personal Care: Used for packaging cosmetic products like lotions, creams, shampoos, face masks, and more. Our machines provide attractive and reliable packaging, enhancing brand image and ensuring product integrity.

- Chemicals: Suitable for packaging chemicals in powders, granules, and liquids. DBAO’s VFFS machines deliver strong, leak-proof seals that maintain the safety and integrity of your chemical products during storage and transport.

- Agricultural Products: Ideal for packaging fertilizers, seeds, pesticides, and other agricultural products. Our machines offer durable, secure packaging that protects the products from external elements, ensuring quality and freshness.